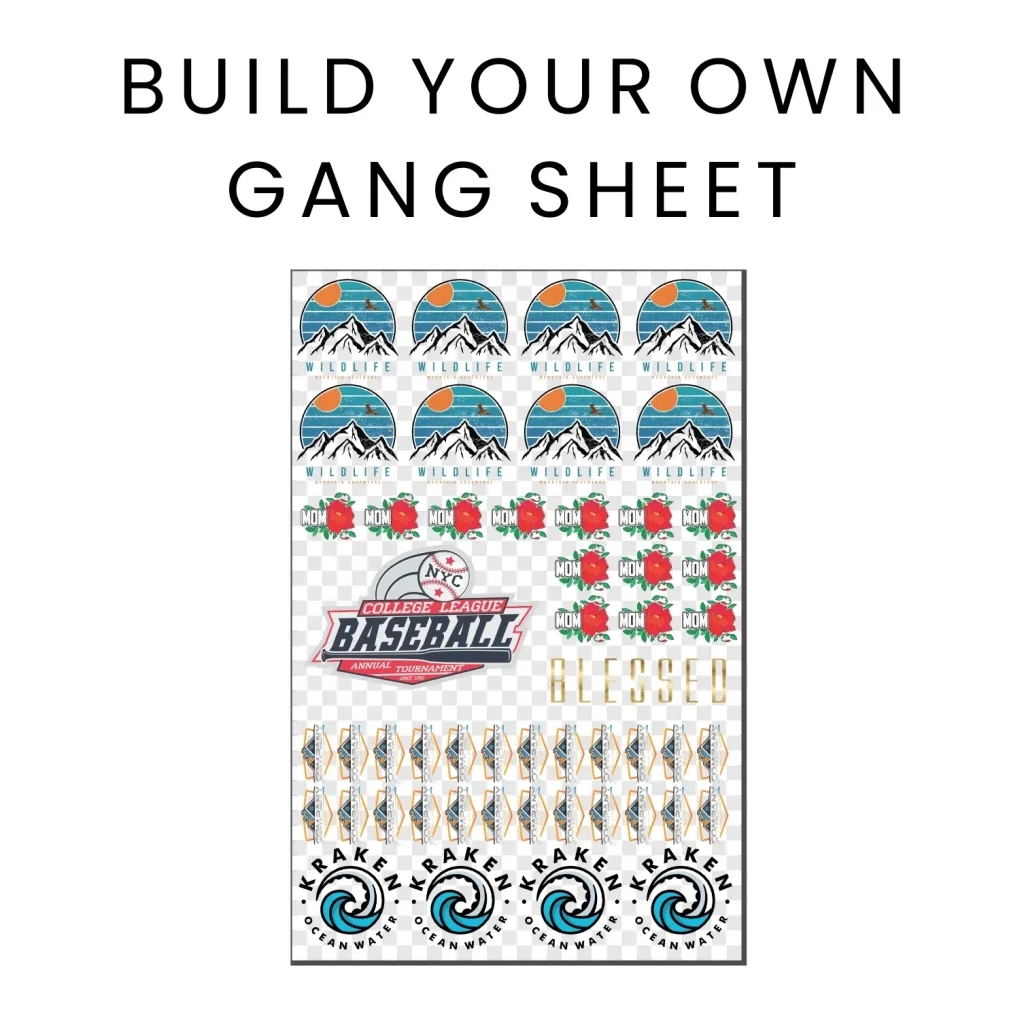

The DTF gangsheet builder is revolutionizing the world of direct-to-film (DTF) printing, offering a cutting-edge solution for designers and printers seeking efficiency without compromising on quality. In an industry where time and cost efficiency in printing matter, this innovative tool optimizes printing workflows by allowing multiple designs to be arranged seamlessly on a single film sheet. Not only does this method significantly reduce material waste, but it also enhances print quality, delivering vibrant colors and crisp graphics that are sure to impress customers. As businesses strive for design flexibility and improved turnaround times, a DTF gangsheet builder becomes essential in meeting competitive demands. In this article, we’ll delve into the benefits of this groundbreaking software and how it can elevate your printing capabilities.

In the realm of garment and substrate decoration, the direct-to-film (DTF) gangsheet creator stands as a transformative solution. By streamlining the process of aligning various designs into one cohesive layout, this tool enhances productivity and minimizes waste, setting a new standard in the printing landscape. Businesses now enjoy optimized workflows that not only reduce operational costs but also maintain superior print quality, ensuring that every project captures the highest level of detail and color vibrancy. As the demand for custom printing increases, employing a gangsheet builder reflects a commitment to both efficiency and innovation. Join us as we explore the multifaceted advantages of integrating this software into your production line.

Understanding DTF Printing and Its Impact on Design

Direct-to-Film (DTF) printing has emerged as a revolutionary method for customizing garments and various substrates, allowing for vibrant and high-quality prints. This printing process involves transferring ink onto film, which is then heat-pressed onto the material, resulting in excellent adhesion and durability. The rise of DTF printing signifies a shift in how designs are applied, promoting a more efficient and versatile printing solution. As a result, brands can meet customer demands for customization while maintaining high print quality and turnaround times.

Moreover, DTF printing integrates seamlessly with modern design philosophies, allowing designers to push boundaries in their creative endeavors. With advancements in technology, the ability to print intricate details has improved dramatically, ensuring that even the finest elements of a design are accurately rendered. This transition not only enhances print quality but also fosters a collaborative environment between designers and printers, where imaginative concepts can quickly become reality.

Maximizing Cost Efficiency in Printing

Cost efficiency is vital in the competitive printing industry, and utilizing a DTF gangsheet builder can lead to significant reductions in overall expenses. By optimizing the layout of multiple designs on a single film sheet, businesses can minimize waste and maximize the material used in each print run. Rather than incurring costs associated with individual setups for separate designs, the gangsheet builder allows printers to efficiently manage their resources, leading to a streamlined production process that enhances profitability.

In addition to less material waste, the DTF gangsheet builder reduces labor costs by consolidating the setup process. When designs can be printed together, the time spent on preparing machines for multiple runs decreases. This shift not only improves workflow efficiency but also allows businesses to redirect their human resources toward other essential tasks, contributing to overall operational enhancement. The result is a more agile business capable of adapting to market demands while keeping costs in check.

Enhancing Printing Workflow Optimization

A well-structured printing workflow is essential for achieving high levels of productivity, and the DTF gangsheet builder plays a crucial role in this optimization. By automating the layout process, this innovative tool simplifies the organization of design files, reducing the time and effort typically spent on manual adjustments. The ability to quickly adapt layouts ensures that production timelines are met, satisfactions are maintained, and orders are fulfilled promptly, which is vital in today’s fast-paced market.

Effective workflow optimization also means leveraging technology that enhances communication and coordination among team members. The integration of digital tools within a DTF gangsheet builder facilitates real-time updates and adjustments, allowing designers to collaborate more effectively with printing teams. This interconnectedness promotes a smoother transition from design to print, ensuring that quality is upheld throughout the production process.

The Role of Design Flexibility in Printing Success

Design flexibility is one of the cornerstones of successful DTF printing, and the DTF gangsheet builder provides unparalleled opportunities for experimentation. This software allows designers to manipulate layouts with ease, making it possible to create multiple versions of designs without committing to individual print runs. Such flexibility is particularly appealing for custom orders, as it allows for personalized touches that resonate with customers.

Furthermore, this adaptability encourages creativity and innovation within the design process. Designers are empowered to test combinations of graphics, colors, and placements, leading to unique offerings that stand out in a crowded market. The ability to quickly modify and visualize changes before printing not only boosts the design process but also enhances customer satisfaction, as clients can see their visions come to life in vibrant detail.

Achieving Improved Print Quality with DTF Technology

Print quality is a decisive factor in customer satisfaction, and the DTF gangsheet builder significantly enhances the overall output quality. When designs are meticulously arranged on gang sheets, it allows for optimal ink coverage and distribution, which is crucial in achieving vividly colored prints with sharp details. DTF printing, combined with the gangsheet technique, minimizes issues such as bleeding and poor adherence, resulting in finished products that meet high-quality standards.

Industry experts agree that enhancements in print technology have made a notable impact on the DTF printing landscape. Regular updates to gangsheet software now enable printers to adjust various parameters, improving the final output’s characteristics. Consequently, businesses can deliver superior print quality that not only meets but exceeds customer expectations, solidifying their reputation in the design and printing industry.

Staying Ahead with Recent Developments in DTF Gangsheet Technology

The landscape of DTF printing continues to evolve with advancements in technology, particularly in the realm of gangsheet builders. Recent developments have introduced artificial intelligence features that streamline the layout process by suggesting optimal arrangements based on the dimensions and characteristics of designs. This innovation removes the burden of guesswork from designers, allowing them to spend more time on creative tasks rather than technical configurations.

The ongoing growth in DTF printing signifies an increasing interest among businesses looking to capitalize on the custom printing market. As DTF gangsheet technology becomes more sophisticated, printers can cater to small-scale orders with ease, meeting the rising demand for high-quality, personalized products. By adopting the latest gangsheet tools, businesses can position themselves as leaders in innovation while ensuring they are equipped to handle the evolving needs of their clientele.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work?

A DTF gangsheet builder is an essential tool in the Direct-to-Film (DTF) printing process, designed to optimize the arrangement of multiple designs on a single film sheet. By allowing printers to efficiently lay out various graphics, the gangsheet builder enhances cost efficiency in printing by reducing material waste and minimizing setup times. This automation streamlines the overall printing workflow, making it faster and more effective.

How does using a DTF gangsheet builder improve print quality?

Using a DTF gangsheet builder significantly improves print quality by ensuring optimal ink distribution across the design. Properly configured gang sheets lead to vibrant colors and sharp images, which are crucial for customer satisfaction. Advanced software features in DTF gangsheet builders help enhance the printing process by recommending the best layouts, further boosting print quality.

What are the cost efficiency benefits of a DTF gangsheet builder?

A DTF gangsheet builder enhances cost efficiency by maximizing film utilization and reducing waste. By combining multiple designs into a single print run, printers save on materials and labor costs tied to individual set-ups. This not only lowers production expenses but also speeds up the printing workflow, leading to higher profitability potential.

In what ways does a DTF gangsheet builder optimize the printing workflow?

A DTF gangsheet builder optimizes the printing workflow by automating the design layout process, reducing the time spent on manually arranging images. This leads to faster print setups and shorter turnaround times for orders, which can significantly enhance overall productivity and customer satisfaction in the printing industry.

Can a DTF gangsheet builder provide design flexibility for custom projects?

Yes, a DTF gangsheet builder offers substantial design flexibility, allowing users to experiment with different arrangements of designs without committing to individual prints. This capability is particularly valuable for custom projects where personalized designs are requested, enabling designers to create unique layouts tailored to customer preferences.

How does the use of a DTF gangsheet builder affect production speed?

The use of a DTF gangsheet builder increases production speed by enabling the simultaneous printing of multiple designs. This streamlined approach allows businesses to fulfill higher quantities of orders in less time, meeting customer demands more efficiently and potentially leading to increased repeat business.

| Key Points | Description |

|---|---|

| Cost Efficiency | Enhances cost efficiency by maximizing film utilization and reducing waste. |

| Increased Production Speed | Allows multiple designs to be printed simultaneously, reducing turnaround times. |

| Design Flexibility | Enables users to adjust layouts and create personalized design options. |

| Reduced Labor Requirements | Automates design organization, freeing up employees for other tasks. |

| Improved Print Quality | Optimizes ink distribution, resulting in vibrant and sharp printed designs. |

Summary

DTF gangsheet builder is transforming the landscape of custom printing by enhancing efficiency and quality. This innovative tool streamlines design processes, cutting down on waste and production time while improving the final output of printed garments. As the demand for custom and high-quality prints continues to rise, incorporating a DTF gangsheet builder into your operations is essential for staying competitive. Embracing this technology not only enhances your service offering but also drives profitability and growth for your printing business.