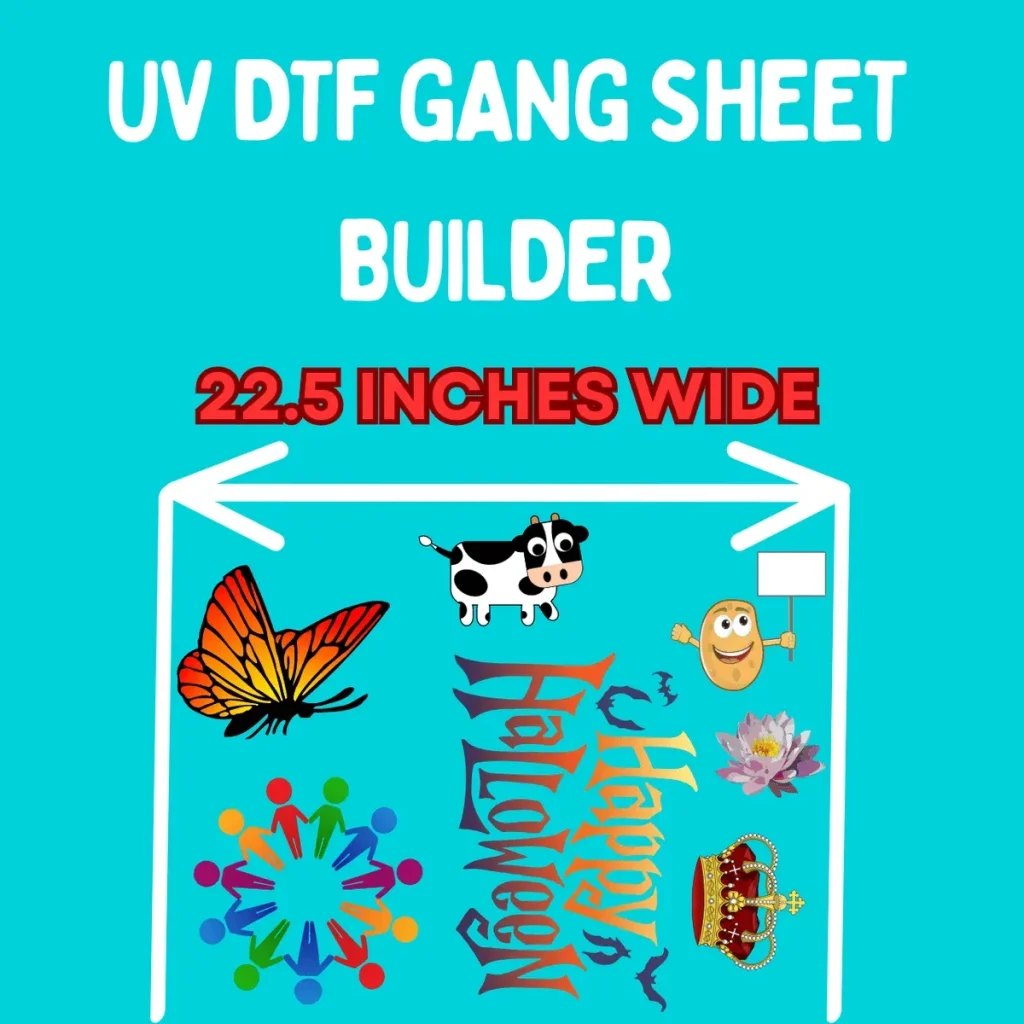

The UV DTF Gangsheet Builder revolutionizes the world of printing by integrating cutting-edge UV printing techniques to produce high-quality, durable prints. This innovative tool allows designers to optimize gangsheet layouts, maximizing the use of space while minimizing material waste. By harnessing the power of DTF printing materials, the builder ensures that every print emerges vibrant and precise, an essential factor in today’s competitive market. Furthermore, understanding color management in printing is crucial for achieving accurate and consistent results, making this builder an indispensable asset for any print professional. Whether you are a small business owner or a large printing facility, utilizing the UV DTF Gangsheet Builder can greatly enhance your production efficiency and final output.

Introducing the UV Direct-to-Film Gangsheet Creator, a game-changing innovation in digital printing that streamlines the process of preparing multiple designs on a single sheet. This advanced print design software leverages the latest in UV printing technology, enabling creators to produce stunning visuals with remarkable durability. By employing a strategic layout method known as gangsheeting, users can maximize their material usage and reduce waste effectively. Additionally, integrating essential practices such as color accuracy and understanding the limitations of inks in UV DTF environments can significantly improve final results. As printing technology advances, embracing tools like the Gangsheet Creator is essential for achieving optimal performance and print quality.

The Importance of Effective Design Layout in UV DTF Printing

Creating an effective design layout is crucial when using your UV DTF gangsheet builder. By meticulously arranging your designs, you can eliminate blank spaces and maximize the printable area on your gangsheet. Utilizing software features such as automatic arrangement tools in Adobe Illustrator or CorelDRAW can simplify the process, making it easier to create a well-organized layout. A thoughtful layout not only enhances the aesthetic appeal of your prints but also leads to reduced material waste, allowing for more efficient use of DTF printing materials.

Moreover, good design layout practices can significantly enhance your print production workflow. By combining smaller designs into a larger gangsheet, you can produce multiple prints in a single run, drastically reducing printing time and costs. This efficiency is particularly beneficial when dealing with larger orders or when rapid turnaround is crucial in your business. Proper design layout ensures you achieve impressive results without compromising on quality.

Understanding Ink Limitations in UV DTF Printing

To achieve the best results with your UV DTF gangsheet builder, it is essential to understand the limitations of the inks you are using. Each UV printer has specific parameters regarding ink usage on different substrates, and exceeding these limits may lead to issues such as ink bleeding and delayed drying times. It’s advisable to consult your printer’s manual for recommended ink volumes to maintain the integrity of your prints. Knowledge of ink limitations not only helps preserve the quality but also prolongs the life of your printer.

In addition, selecting the right ink type for your specific substrates is vital. UV inks offer vibrant colors and strong adhesion, but their performance can vary based on the material used. Experimenting with different inks can provide valuable insights into achieving optimal print quality. Understanding these limitations and characteristics of your UV DTF inks enables you to fine-tune your printing process, leading to better outcomes and satisfied clients.

Prioritizing Color Management for Optimal Outcomes

Color management is a paramount consideration in UV DTF printing. Accurate color representation from design to print is crucial for client satisfaction and brand consistency. Before embarking on your print runs with the gangsheet builder, ensure the proper ICC profiles are installed in your print design software. These profiles help translate onscreen colors to their real-world counterparts, ensuring that your final prints reflect the intended design accurately.

Additionally, you may need to adjust various color settings, such as brightness, saturation, and hue, depending on the nature of the substrates you are using. Different materials can absorb and reflect colors differently, which may require further adjustments to achieve consistent results. By maintaining stringent color management practices throughout your printing process, you can ensure that your UV DTF prints consistently meet quality standards and exceed client expectations.

Choosing the Right DTF Printing Materials for Success

The materials you select play a crucial role in the success of your UV DTF printing projects. With a variety of options available, including cotton, polyester, and plastics, it’s essential to evaluate which substrate will best suit your specific designs and desired finishes. Each material carries distinct properties that can affect ink adhesion, color vibrancy, and overall durability. Experimenting with various DTF printing materials allows you to find the perfect match for your projects.

Furthermore, considering the type of finish you wish to achieve—be it matte, glossy, or textured—can guide your material selection process. Different substrates yield varying results in terms of print finishing and feel, impacting the final product’s quality. By prioritizing the choice of materials, you set the foundation for successful UV DTF printing outcomes that align with client specifications and market trends.

Regular Maintenance and Calibration of UV Printers

Maintaining your UV printer is essential to preserving its performance and ensuring high-quality outputs when using a gangsheet builder. Regularly cleaning the print heads and inspecting ink systems for potential clogs can prevent printing issues that affect color accuracy and consistency. Schedule routine maintenance checks to avoid unexpected breakdowns, which could lead to production delays and increased costs.

In addition to cleaning, calibrating your printer regularly is crucial for achieving reliable print quality. Calibration involves adjusting settings to ensure that color output remains consistent across different jobs. This step is particularly important in high-volume production environments, where maintaining uniformity across prints is essential for client satisfaction and brand integrity.

Post-Printing Processes: Ensuring Durability and Quality

Once your prints are completed using the UV DTF gangsheet builder, allowing sufficient curing time is vital for the durability of your products. Proper exposure to UV light not only solidifies the inks but also enhances the prints’ resistance to fading and scratching. Neglecting this step can lead to compromised print quality and longevity, which could ultimately affect customer satisfaction and repeat business.

Additionally, handling prints with care post-production is necessary to prevent smudging or damaging the final product. Employing protective measures during this phase, such as appropriate storage solutions, can help maintain the integrity of your prints until they reach the client. By focusing on thorough post-printing processes, you can ensure that your UV DTF prints deliver exceptional quality and durability.

Frequently Asked Questions

What is a UV DTF gangsheet builder and how does it improve my printing process?

A UV DTF gangsheet builder is a tool that allows designers to layout multiple images for printing on a single sheet using UV Direct-to-Film technology. It optimizes the use of printable area, reduces material waste, and enhances efficiency by enabling simultaneous printing, which leads to quicker turnaround times and cost savings.

How do I effectively manage ink limitations when using the UV DTF gangsheet builder?

To effectively manage ink limitations with your UV DTF gangsheet builder, refer to the specifications of your UV printer regarding ink capacity on various substrates. Avoid overloading your gangsheet to prevent issues such as ink bleeding and color inaccuracies. Always follow the recommended ink volume to ensure high-quality, vibrant outputs.

What role does color management play in UV DTF printing with a gangsheet builder?

Color management is crucial in UV DTF printing as it ensures that the colors you see on your screen match the final prints. Before printing with a gangsheet builder, make sure to use correct ICC profiles in your print design software, and adjust brightness, saturation, and hue as needed to achieve accurate color reproduction across different substrates.

What types of DTF printing materials work best with a UV DTF gangsheet builder?

The best DTF printing materials for use with a UV DTF gangsheet builder include cotton, polyester, and a variety of plastics. Choosing the right material depends on the desired finish—whether matte or glossy—and the specific project requirements. Experimenting with different substrates can help you find the most compatible options for optimal output.

How often should I perform maintenance on my UV printer used for DTF printing?

Regular maintenance of your UV printer is vital for consistent print quality. Schedule routine checks to clean print heads, inspect ink systems for clogs, and calibrate the machine. This proactive approach helps prevent issues, maintaining the vibrant quality of prints produced with your UV DTF gangsheet builder.

What are some post-printing processes I should follow for UV DTF prints made with a gangsheet builder?

After printing with your UV DTF gangsheet builder, allow sufficient time for proper curing under UV light to ensure inks are solidified for durability and fade resistance. Handle the prints carefully post-curing to avoid smudging or damage, thereby preserving the quality and longevity of the final product.

| Key Points | Details |

|---|---|

| Understanding UV DTF Printing | Utilizes UV light to cure inks, allowing for high-quality prints on various materials. |

| Effective Design Layout | Strategically position designs to minimize blank spaces and maximize usage. |

| Know Your Ink Limitations | Avoid ink bleeding and ensure optimal volume for print quality. |

| Prioritize Color Management | Use correct ICC profiles for accurate color representation. |

| Select Appropriate Materials | Choose the right substrates for desired outcomes based on finish. |

| Maintenance and Calibration | Regular checks ensure consistent quality and prevent issues. |

| Post-Printing Processes | Allow adequate curing time for durable prints. |

Summary

The UV DTF Gangsheet Builder is an essential tool for maximizing print quality and efficiency in UV Direct-to-Film printing. By understanding its functionalities and integrating best practices—such as effective layout design, ink management, and appropriate material selection—you can produce vibrant and enduring prints. This approach not only enhances operational productivity but also elevates the final print results, making it easier to meet the demands of both professional projects and creative endeavors. As the technology continues to evolve, leveraging these strategies will keep you at the forefront of the printing industry.