The DTF gangsheet builder is revolutionizing the textile printing industry, offering businesses a powerful tool to maximize production and optimize efficiency. With its ability to arrange multiple designs on a single transfer sheet, this innovative software enhances direct-to-film printing by significantly reducing material waste and overall costs. By leveraging the precision of a DTF gangsheet builder, companies can streamline their operations, align with the latest textile printing trends, and ensure a higher standard of appliance efficiency. In this blog post, we will delve into the myriad benefits of utilizing DTF printing software, exploring its impact not only on production capabilities but also on sustainable practices within the industry. Join us as we uncover how to fully harness this technology to boost your business’s success.

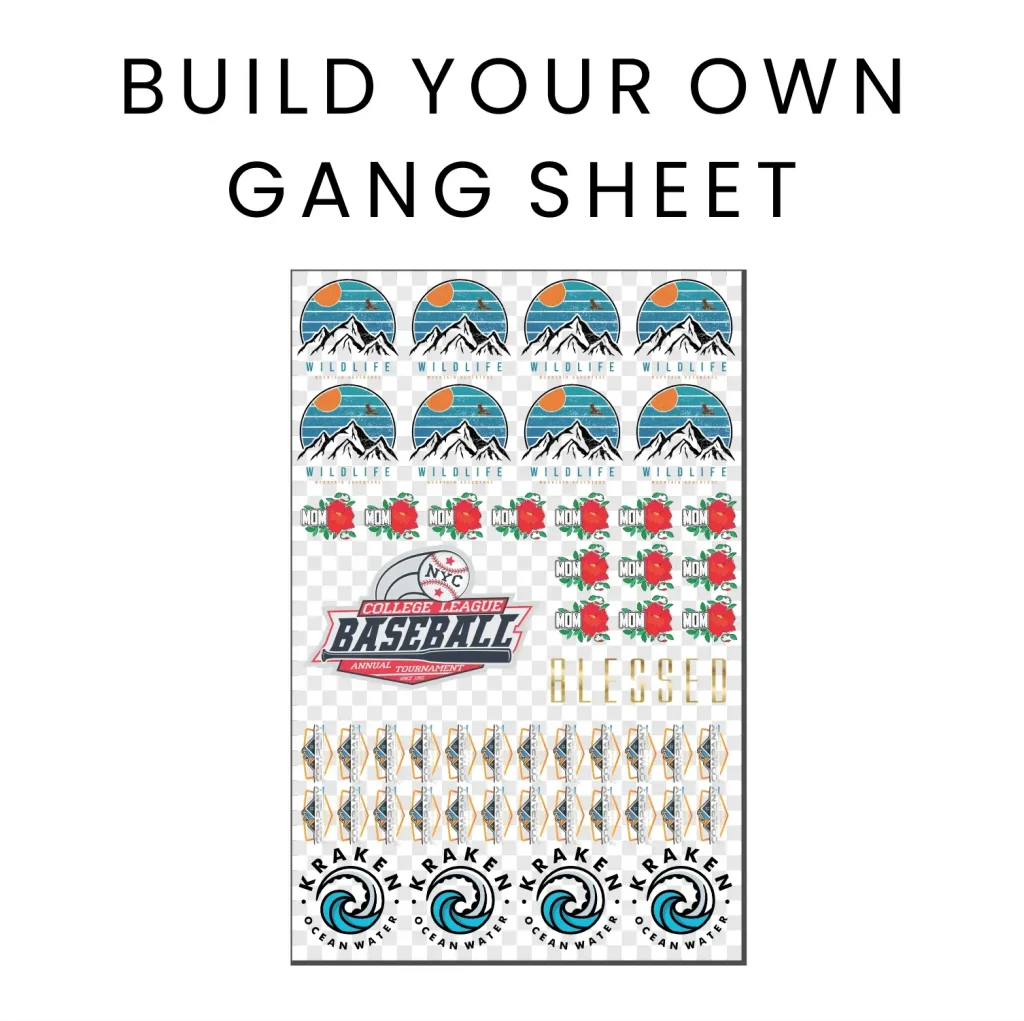

When discussing effective solutions in the realm of digital textile printing, the concept of a DTF gangsheet creator often emerges. This advanced tool facilitates the organization and placement of various designs onto a single film transfer, ensuring that every piece of material is utilized efficiently. As more apparel businesses adopt direct-to-film methods, the importance of maximizing print output while keeping costs low becomes increasingly clear. Synonymous with terms like layout optimizer and transfer film manager, this tool allows users to navigate the complexities of modern printing workflows with greater ease, ultimately contributing to elevated production rates and enhanced design versatility.

Understanding the Impact of DTF Printing on Production Efficiency

Direct-to-Film (DTF) printing has significantly revolutionized the production processes within the textile industry. By enabling high-quality designs to be transferred directly onto fabrics, DTF technology not only enhances visual appeal but also promotes production efficiency. Businesses utilizing DTF printing can produce intricate designs that were often challenging with traditional methods, allowing designers greater creative freedom while reducing lead times. This growing reliance on DTF methodologies showcases a trend toward optimizing production workflows, enabling factories to maximize their output while maintaining quality.

Furthermore, production efficiency is heavily influenced by how manufacturers adapt to DTF printing techniques. As industry standards evolve, the focus shifts toward streamlining operations—especially regarding material use and machine deployment. Companies integrating DTF methods have reported notable increases in output capacity and a decrease in waste, ultimately leading to enhanced profitability. As businesses embrace this workflow transformation, they gain a competitive edge by meeting consumer demand more promptly and effectively.

Key Features to Look for in a DTF Gangsheet Builder

When choosing a DTF gangsheet builder, it’s crucial to consider features that enhance usability and maximize production capabilities. Software solutions should offer intuitive interfaces that allow users to easily arrange multiple designs on a single sheet of transfer film. Additionally, automation features play a significant role in expediting the gangsheet creation process, enabling users to focus on creativity rather than tedious tasks. Ideal gangsheet builders will also aid in maintaining optimal spacing and alignment, thus minimizing film waste.

Another important aspect is the software’s integration capabilities with existing DTF printers and equipment. A robust DTF gangsheet builder should be compatible with various printer models to ensure optimum results across different production setups. Moreover, ensuring that the software includes functionalities to adjust print settings according to the type of fabric and ink used will enhance overall appliance efficiency, directly contributing to better-quality outputs and reduced costs.

Strategies for Effective Layout Optimization

Effective layout optimization is critical in maximizing production through a DTF gangsheet builder. One way to improve layout efficiency is by employing techniques such as grouping similar designs together based on size and shape. This organization minimizes wasted space and maximizes the use of each transfer film sheet, ultimately driving down film costs and production time. Additionally, utilizing software features that suggest the best arrangement can further ease the planning process, allowing for a more calculated and effective production approach.

Regularly reviewing and analyzing layout strategies can also yield significant operational benefits. Businesses should monitor their material usage closely and identify patterns in design placement that lead to excess waste. By experimenting with different configurations and documenting the results, manufacturers can continually refine their gangsheet layouts to achieve the best possible efficiency. This iterative approach not only enhances current practices but keeps operations flexible to adapt to changing textile printing trends.

Environmental Benefits of Using DTF Gangsheet Builders

Utilizing a DTF gangsheet builder offers significant environmental advantages, particularly in reducing material waste associated with traditional printing methods. By optimizing how designs are arranged on transfer films, businesses can significantly lower their consumption of resources. This waste reduction not only decreases direct material costs but also diminishes the overall environmental footprint of printing operations. As sustainable practices become increasingly important to consumers, adopting DTF technologies becomes a strategic move for companies looking to align with eco-friendly values.

Moreover, eco-conscious consumers are more likely to support brands that demonstrate sustainable practices. By leveraging DTF gangsheet builders to efficiently use resources and minimize waste, companies can build a reputation for environmental responsibility. This proactive stance not only helps in reducing operational costs but can also enhance brand loyalty and customer relations, ultimately contributing to long-term business sustainability.

The Importance of Integration in DTF Printing Workflows

Integrating a DTF gangsheet builder into the broader production workflow is essential to fully leverage its potential benefits. Proper integration ensures seamless communication and collaboration among different stages of the production process—from design conception to final application. By aligning print production with cutting and application processes, businesses can significantly enhance efficiency and reduce the likelihood of errors, which can waste valuable materials and time.

Training employees on the significance of integration within their production tasks cannot be overlooked. It’s crucial that everyone on the team understands how the gangsheet builder fits into the overall workflow and how their roles impact efficiency. By fostering a culture of teamwork and communication, companies can capitalize on the technological advantages provided by DTF printing and gangsheet building, making for a more cohesive and effective production environment.

Emerging Trends in DTF Technology for Enhanced Production

The DTF printing landscape is constantly evolving, and staying abreast of emerging trends can position businesses for greater success. Significant innovations, such as the use of eco-friendly inks, provide opportunities for companies to change their operations sustainably while meeting consumer demands for greener products. Adopting these technologies often allows businesses to maximize production capabilities without sacrificing quality or environmental responsibility.

Moreover, advancements in printing technology, including faster machines designed to handle multiple gang sheets concurrently, are significantly boosting production speed. These innovations not only save time but also enhance the overall efficiency of textile operations. Companies that adopt these latest trends are better equipped to respond to market changes, ensuring continual growth and competitiveness in an increasingly dynamic industry.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it maximize production?

A DTF gangsheet builder is a specialized tool or software that allows users to organize multiple designs on a single sheet of transfer film, optimizing layout to maximize production output. By efficiently utilizing the printing space, it reduces material waste, thus lowering costs and improving overall appliance efficiency in DTF printing operations.

How can I achieve better material efficiency with a DTF gangsheet builder?

By using a DTF gangsheet builder, businesses can arrange designs to minimize waste and maximize the use of transfer film. This leads to a significant reduction in material costs and contributes to sustainable practices in textile production, making it a smart choice for efficient DTF printing.

What are the latest trends in DTF printing software that enhance gangsheet building?

Recent trends in DTF printing software include eco-friendly inks and high-speed printers capable of managing multiple gang sheets. These advancements enable faster production times and better sustainability, allowing businesses to stay competitive while efficiently using a DTF gangsheet builder.

How does layout optimization affect DTF printing costs?

Effective layout optimization through a DTF gangsheet builder can lead to cost savings of up to 30% on transfer film. By arranging designs closely and efficiently, businesses can significantly reduce excess blank areas, thereby minimizing material waste and enhancing overall production efficiency.

What design considerations should I keep in mind when using a DTF gangsheet builder?

When using a DTF gangsheet builder, consider item dimensions, spacing between designs to prevent overlaps, and ensuring visual appeal in the arrangement. These factors are crucial for both operational efficiency and maintaining the aesthetic quality of the final printed textiles.

How can I integrate a DTF gangsheet builder into my textile printing workflow?

To effectively integrate a DTF gangsheet builder into your workflow, ensure all team members are trained on layout efficiency. Organize processes for printing, cutting, and application, and utilize software tools that streamline these operations, leading to improved turnaround times and production reliability.

| Key Points | Details |

|---|---|

| Introduction | DTF printing efficiently transfers designs onto fabrics, with gangsheet builders optimizing transfer film use. |

| What Is a DTF Gangsheet Builder? | A software tool that organizes multiple designs on a single transfer film sheet, reducing waste and maximizing output. |

| Importance of Layout Optimization | Efficient layout can save up to 30% on transfer film costs for DTF businesses. |

| Leading Software Options | Cadlink, AgiSoft, and specialized DTF software automate design processes and ensure print accuracy. |

| Design Considerations | Consider item dimensions, spacing, and visual appeal for effective layouts. |

| Material Efficiency | Lower film waste and costs promote quality and sustainability. |

| Workflow Optimization | Integration of gangsheet building in operations for faster production turnaround. |

| Latest Trends | Adoption of eco-friendly inks and faster printing technologies in the DTF market. |

Summary

The DTF gangsheet builder plays a pivotal role in streamlining the production process in the textile and apparel industry. By optimizing layout and maximizing material efficiency, it allows businesses to significantly reduce costs while enhancing quality. Embracing design consideration and integrating advanced software solutions can further propel production capabilities. In today’s competitive landscape, leveraging a DTF gangsheet builder is not just a strategic advantage but a necessity for businesses aiming to thrive and maintain sustainability in their operations.