Understanding DTF transfer size is crucial for achieving the perfect design fit in the world of Direct-to-Film (DTF) printing. This innovative technology allows for vibrant, intricate prints on a variety of fabrics, but getting the dimensions right based on garment sizing can make or break the final product. In this article, we will explore effective transfer techniques and the important factors of print area measurement, ensuring that your designs appear flawless regardless of size. By mastering heat transfer settings and adjusting for varying garment sizes, you can significantly enhance the quality of your prints. Dive in with us as we share essential tips for achieving optimal fit and finish in your DTF printing projects.

When it comes to the sizing of DTF transfers, it’s essential to grasp the intricacies of heat transfer printing and its impact on fabric applications. This technique has opened up new avenues for creative expression in garment decoration, yet the success of each print relies heavily on accurate dimensions. Exploring concepts related to garment dimensions, and print scaling is vital to ensure that designs translate perfectly from film to fabric. By examining various transfer methods and their compatibility with differing textile sizes, you can avoid common pitfalls and achieve outstanding results. Join us as we unravel the art of sizing in DTF printing, aiming for impeccable designs that resonate with your brand’s vision.

Understanding DTF Transfer: Key Concepts

Direct-to-Film (DTF) printing is a groundbreaking method that enhances the way designs are applied to garments. The process involves printing designs onto a special film which is then transferred onto fabric using heat. This technique ensures vibrant colors and detailed images that stand out on various textile materials. To get the most out of DTF transfers, understanding essential concepts like garment sizing and transfer techniques is crucial.

When utilizing DTF printing, it’s important to remember that each garment size may require adjustments in the design scaling process. The print area measurement significantly impacts the final outcome; a standard size might not translate well to larger or smaller sizes. By mastering these concepts, businesses can ensure that their designs fit perfectly on any garment, maintaining the quality and integrity of the print.

Garment Sizing and DTF Transfers: A Perfect Match

Garment sizing plays a vital role in the DTF transfer process. Each size of a garment presents unique challenges when it comes to scaling the design. For example, a print intended for a small t-shirt will not only need to be resized to fit a larger shirt but should also consider the overall proportions to preserve aesthetics and clarity of the design. A common mistake is failing to adjust the print area measurement appropriately, which can lead to distorted or poorly aligned graphics.

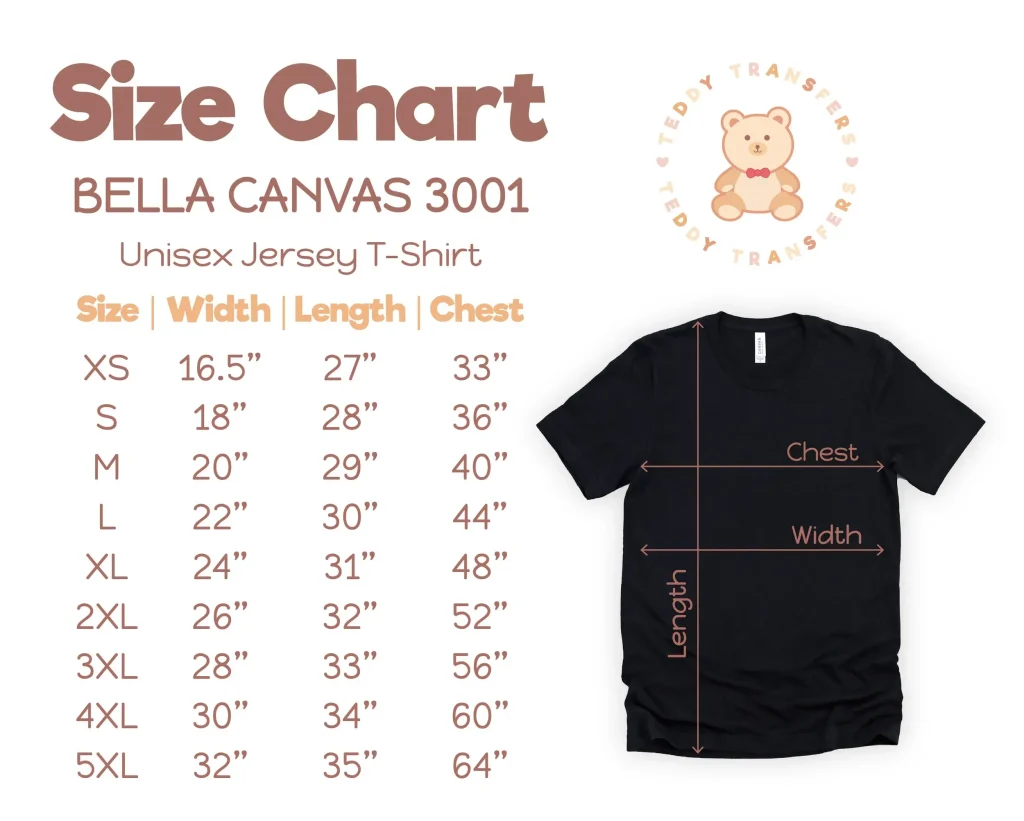

To ensure a perfect match of design and size, it’s advised to create a sizing chart that correlates with your garments. This chart should include information on the print area measurement for each size variant. By referencing this when designing graphics for DTF transfers, you can streamline your printing process and enhance customer satisfaction, as the finished products will accurately reflect your brand’s quality.

Essential Tips for Accurate Print Area Measurement

Accurate print area measurement is critical for effective DTF transfer application. Before embarking on the printing process, carefully measure the area where the design will be applied. This includes considerations for seams, collars, and any other structural elements of the garment that could affect the final look. Understanding the available space will help prevent errors that could arise from misjudged print placements.

Utilizing templates can significantly enhance accuracy when measuring print areas. By creating digital templates for various sizes, you can easily visualize how the design will fit on different garments. This approach not only helps in achieving precision but also promotes consistency across various prints. Furthermore, leveraging heat transfer settings in tandem with measured print areas will yield the optimal finish that customers expect from high-quality DTF prints.

Adapting Transfer Techniques for Different Sizes

Each garment size may require a different approach when it comes to transfer techniques. For instance, while a straightforward heat transfer may suffice for smaller items, complex designs on larger garments might benefit from multiple layers or different transfer methods to ensure the detail remains intact. Understanding these nuances is essential for those looking to maximize the efficiency of their DTF printing methods.

Experimenting with various transfer techniques can also lead to innovative results. Consider using overlapping prints for larger sizes or creating complimentary color layers that work well together. Each garment presents an opportunity to showcase creativity; adapting transfer techniques accordingly ensures that businesses can cater to a diverse range of customer preferences while maintaining product quality.

Optimizing Heat Transfer Settings for DTF Prints

Heat transfer settings are paramount when executing a successful DTF transfer. The temperature, pressure, and duration of heat application directly influence the adhesion of the print to the garment. A common issue faced by printers is applying too much heat or not enough, which can lead to peeling or fading of the transfers. Finding the right balance is essential and can often be achieved through trial and error on scrap fabrics before finalizing on actual garments.

Furthermore, the fabric type also affects how heat transfer should be applied. Materials such as cotton, polyester, and blends will respond differently to heat settings. Therefore, it is worth investing time to test various combinations of heat settings based on the specific garment type to achieve the best results. Effective adjustment and optimization of these settings will ensure that the DTF transfers not only adhere well but also last through multiple washes.

Best Practices for DTF Printing Across Sizes

Adopting best practices in DTF printing can vastly improve the consistency and quality of your garments. Start by refining your design files to ensure that they are high-resolution and appropriate for the intended print area measurement. This attention to detail helps prevent issues such as pixelation and blurriness in prints, especially on larger sizes where visual impact is key.

Moreover, establishing a standardized workflow that includes testing, measuring, and verifying designs before mass production can save time and resources. It’s also beneficial to keep abreast of new developments within DTF printing technology and explore innovative techniques that may provide better results or efficiency. By applying these best practices, businesses can ensure not only high-quality prints but also a dependable reputation for excellence.

Frequently Asked Questions

What is DTF transfer size and why is it important in DTF printing?

DTF transfer size refers to the dimensions of the transfer film used in Direct-to-Film (DTF) printing. It’s crucial because the size of the transfer affects how well the design fits on the garment. Proper measurement ensures that the design complements the garment’s sizing, promoting an aesthetically pleasing appearance.

How do I determine the correct garment sizing for my DTF transfers?

To determine the correct garment sizing for DTF transfers, measure the print area of the garment. This involves understanding both the dimensions of the transfer design and the specific areas of the garment where the design will be applied. Matching the DTF transfer size to the garment’s sizing helps achieve a professional finish.

What are the best practices for print area measurement when using DTF transfers?

Best practices for print area measurement in DTF transfers include using a measuring tape to assess the width and height available on the garment. Consider the design elements and how they fit within the garment’s structure. This ensures the DTF transfer size is optimized for both visibility and aesthetics.

Can different transfer techniques affect the DTF transfer size?

Yes, different transfer techniques, such as heat transfer methods and the type of film used, can impact the optimal DTF transfer size. Some techniques may require adjustments in sizing to adhere properly to various fabric types, which is essential for durability and design clarity.

What heat transfer settings are recommended for various DTF transfer sizes?

Recommended heat transfer settings for DTF transfers vary depending on the transfer size and the fabric type. Generally, a temperature range of 300-330°F and a pressing time of 10-15 seconds are effective. However, adjustments based on the specific transfer size may be necessary to ensure proper adhesion without damaging the fabric.

How can I scale my designs effectively for different DTF transfer sizes on various garments?

To scale designs effectively for different DTF transfer sizes, use software tools to resize the graphic according to the print area measurement of each garment. Before printing, test the scaled design on a sample fabric to ensure that the DTF transfer achieves the desired look across various garment sizes.

| Key Point | Details |

|---|---|

| DTF Transfer Technology | Revolutionizes the textile industry by enabling high-quality designs on fabrics. |

| Garment Size Adjustment | Understanding how to size DTF transfers according to garment dimensions is crucial for optimal results. |

| Tips for Perfect Fit | Important techniques include accurate print area measurement, correct transfer techniques, and heat settings. |

| Focus and Related Keywords | The main focus keyword is ‘DTF Transfer Size’ with related keywords like DTF printing, garment sizing, etc. |

| SEO Optimization | An SEO-friendly title and meta description enhance online visibility for those seeking DTF transfer information. |

Summary

DTF Transfer Size is a crucial aspect of mastering Direct-to-Film transfer technology, particularly for businesses aiming to achieve perfect designs on a variety of garments. Understanding how to effectively adjust DTF transfers according to garment sizes is essential for producing high-quality results. This involves measuring print areas accurately, using proper transfer techniques, and setting the heat transfer settings appropriately. By incorporating these tips, print shops can enhance their product offerings while ensuring that each design fits perfectly on its intended fabric. With the right knowledge and approach, organizations can maximize the potential of DTF technology and create stunning apparel that meets customer expectations.