The **DTF Gangsheet Builder** is a game-changer in the realm of custom printing, offering unparalleled advantages for those engaged in DTF printing technology. Mastering this tool is essential for optimizing your workflow and maximizing printing efficiency. With the right strategies, you can streamline your gangsheet layout, which means getting more prints from less material and thereby reducing waste. This introduction will explore effective printing efficiency tips that can elevate your production quality and output. Stay tuned as we dive into the key elements necessary to enhance your DTF printing capabilities through smart organization and design.

In the landscape of custom graphics and textile printing, the concept of a **DTF gangsheet builder** encompasses a multifaceted approach to the Direct to Film (DTF) printing method. By utilizing sophisticated design layouts, printmakers can greatly enhance their operational workflows, ensuring that each print job achieves optimal utilization of resources. Understanding the importance of DTF printing is crucial for professionals looking to elevate their output, while strategies for optimizing the entire process can yield significant gains in productivity. Moreover, leveraging advanced tools and software is vital in creating the ideal gangsheet layout, ensuring that no material goes to waste. Dive into the intricacies of this innovative workflow to discover how to make your DTF printing journey a resounding success.

Understanding DTF Printing Technology

DTF printing technology represents a significant leap in the custom printing landscape, allowing for high-quality prints with vibrant colors and exceptional detail. Mastering the intricacies of this technology is crucial for any printer aiming to produce top-notch products. It’s vital to comprehend how the DTF process leverages both film and specialized inks to transfer designs onto various fabrics. Understanding the scientific principles behind DTF can enhance your ability to troubleshoot issues and enhance overall output quality.

Moreover, staying current with advancements in DTF technologies can open doors to new techniques and materials that could significantly improve your workflow. Emerging technologies, such as improved ink formulations, are constantly being released, promising better adhesion, faster curing times, and enhanced color vibrancy. Regularly researching these innovations not only keeps you informed but can position your business at the forefront of the DTF printing industry.

Maximizing Efficiency with DTF Gangsheet Builder

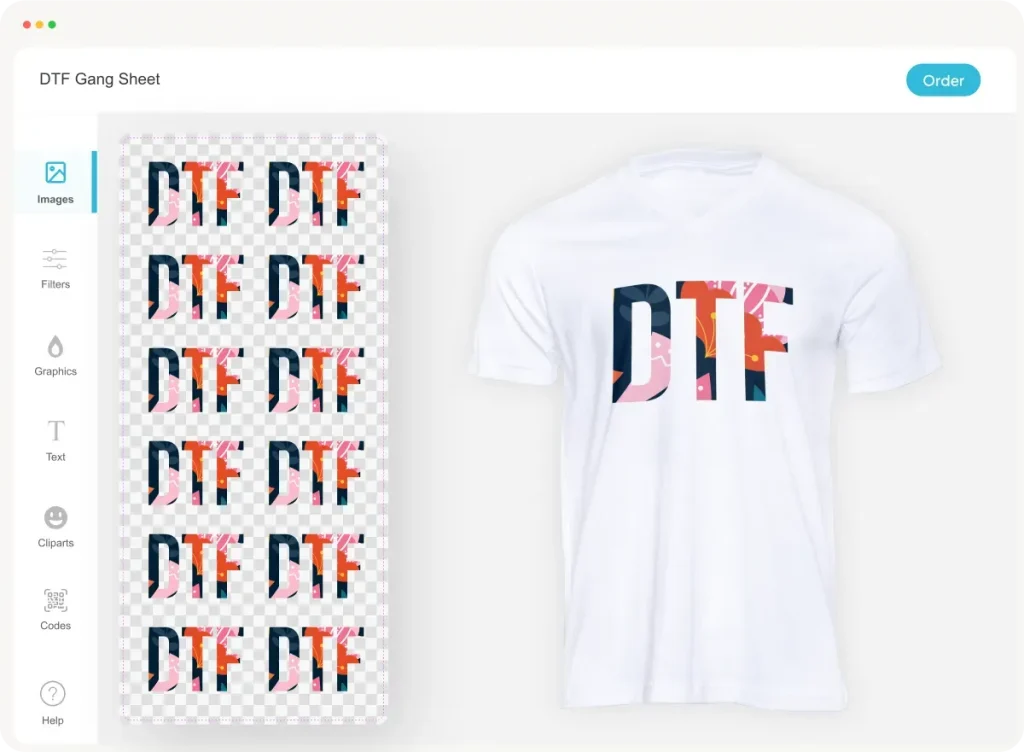

The DTF gangsheet builder is an essential tool for optimizing printing efficiency. When utilized correctly, it helps facilitate the arrangement of multiple designs on a single film sheet. This capability is crucial as it reduces material waste and enhances production workflow. By effectively using a gangsheet builder, you can streamline your printing setup, allowing for a broader range of designs to be printed simultaneously without sacrificing quality.

Incorporating layout best practices, such as grouping similar designs and aligning them to fit snugly within the gangsheet, can further optimize material use. This meticulous arrangement not only saves on costs but also reduces printing time by maximizing the number of prints produced in one go. Through trial and error, finding the most compatible and effective layout can lead to exponential improvements in overall productivity.

Software Solutions for Optimized DTF Workflow

Utilizing advanced software solutions is a critical component of successfully optimizing your DTF workflow. Programs specifically designed for DTF printing often come equipped with features that facilitate automation and streamline design processing. This allows for tasks such as resizing, color matching, and template management to be executed with ease. Automating repetitive tasks can substantially increase efficiency, enabling you to focus time on more impactful aspects of the printing process.

Additionally, investing in high-quality design software can significantly enhance output quality. Not only does it allow for greater control over the design elements, but it also integrates seamlessly with your existing DTF setup. This integration ensures optimal color fidelity and design placement, which ultimately leads to a more polished final product. Regularly exploring software updates and new tools can keep your workflow aligned with industry best practices.

Effective Layout Techniques for Gangsheet Optimization

The layout of designs on your gangsheet is paramount to optimizing material utilization in DTF printing. By employing effective layout techniques, you prime your production process for efficiency and cost-effectiveness. Strategies such as limiting white space between designs and utilizing a grid layout can enhance the use of available print areas. The goal is to strike a balance between maximizing output while ensuring that the prints do not interfere with one another during the transfer process.

Moreover, using design software that offers layout optimization features can be incredibly beneficial. Such software can help identify the most efficient placements and flag potential overlapping designs, minimizing costly errors during printing. These layout strategies not only streamline the workflow but also contribute to higher customer satisfaction by ensuring a higher-quality print with less waste.

Quality Control Practices in DTF Printing

Implementing a strong quality control system in your DTF printing process is vital for maintaining product standards. Regularly inspecting printed outputs for color accuracy, clarity, and alignment can prevent costly reprints and ensure that the final products meet your clients’ expectations. Enforcing quality checks at various stages of production fosters a culture of excellence and can significantly enhance overall efficiency by catching errors early in the workflow.

Establishing a feedback loop within your team can also streamline the quality control process. By encouraging open communication about quality issues, print operators can quickly identify and rectify mistakes, which reduces downtime and improves output quality. Creating clear quality benchmarks and incorporating them into standard operating procedures will lead to consistent results and boost customer satisfaction.

Investing in Training for DTF Printing Success

Investing in team training is essential for optimizing productivity within your DTF printing operations. Continuous learning opportunities, such as workshops, online courses, or hands-on training sessions, equip your team with the necessary skills to handle the latest DTF printing technologies and software. Knowledgeable employees are more likely to leverage their skills effectively, leading to higher-quality prints and an overall smoother workflow.

Incorporating regular training sessions ensures that your team remains updated on the best practices within DTF printing. This commitment to education not only fosters skill growth but also promotes team cohesion, enabling employees to collaborate more effectively. As a result, your DTF printing business can stay competitive and agile in a fast-evolving industry.

Frequently Asked Questions

What is the DTF Gangsheet Builder and why is it important for DTF printing?

The DTF Gangsheet Builder is a crucial tool in the DTF printing process that allows users to create optimal layouts for prints on a gangsheet, maximizing material efficiency and minimizing waste. It enhances productivity by enabling designers to arrange multiple designs strategically within a single print run.

How can I optimize the layout of my designs in the DTF Gangsheet Builder?

To optimize your layout in the DTF Gangsheet Builder, ensure that your designs are arranged closely together to minimize unused space. Utilize layout software features to avoid overlapping prints, which can result in wasted materials and production delays.

What printing efficiency tips should I consider when using the DTF Gangsheet Builder?

Key printing efficiency tips for the DTF Gangsheet Builder include understanding your printer’s capabilities, automating repetitive tasks with software, maintaining a clutter-free layout, and implementing a regular quality control system to ensure high print quality and minimize reprints.

How can software tools enhance my DTF Gangsheet Builder workflow?

Software tools can significantly enhance your DTF Gangsheet Builder workflow by offering automation features for design iterations, template management, and improved integration with your DTF printing technology. Investing in software designed for DTF applications can streamline processes and boost overall efficiency.

What are the latest trends in DTF printing technology relevant to the DTF Gangsheet Builder?

The latest trends in DTF printing technology include advancements in ink formulations for vibrant colors, faster drying times, and automation features in design software that integrate with the DTF Gangsheet Builder, all of which contribute to improved print quality and workflow efficiency.

How can I stay informed about updates and best practices for the DTF Gangsheet Builder?

Stay informed about updates and best practices for the DTF Gangsheet Builder by participating in industry webinars, joining professional forums, and connecting with other DTF printing professionals. Engaging in these communities can provide valuable insights into the latest technologies and efficient workflows.

| Key Aspect | Tips for Optimization |

|---|---|

| Understand Your Printer and Inks | – Know printer specifications – Consider color output and drying times – Stay updated with technology |

| Utilize Software Optimization | – Use software with automation features – Invest in high-quality design programs |

| Optimize Layout | – Maximize material usage – Avoid overlapping designs |

| Implement Quality Control | – Conduct regular inspections – Establish a feedback loop |

| Stay Updated with Industry Trends | – Attend webinars and seminars – Network with other professionals |

| Training and Skill Development | – Enroll in online courses – Carry out hands-on training sessions |

| Leverage Community Resources | – Participate in online forums – Engage with DTF user groups |

Summary

DTF Gangsheet Builder optimization is essential for enhancing your printing operations. By gaining a comprehensive understanding of your equipment, leveraging advanced software tools, and adopting effective layout strategies, you can significantly streamline your workflow. Implementing rigorous quality control measures and staying abreast of industry trends will not only elevate your product quality but also boost your overall productivity. Investing in the training and development of your team and engaging with the DTF community can further enrich your skill set and resource base. Take action on these strategies today to transform your DTF printing processes and achieve remarkable results!