When it comes to DTF transfer dimensions, choosing the right size is crucial for achieving the best results in garment printing. DTF printing, or Direct-to-Film printing, allows for vibrant and durable designs to be transferred onto a variety of fabrics, but understanding the dimensions of your transfers can enhance their effectiveness. Proper DTF transfer sizes can range from standard formats like A3 and A4 to custom specifications tailored for unique apparel. This guide will delve into how to choose DTF dimensions that align perfectly with your projects, ensuring a seamless integration of your designs. By mastering DTF transfer dimensions, you will improve both the visual impact and overall quality of your garment transfer printing endeavors.

In the realm of textile design and printing, knowing the right sizes for your Direct-to-Film transfers—also known as garment transfer dimensions—can significantly influence the success of your projects. DTF, or Direct-to-Film, printing has gained traction as an innovative method for applying bright and lasting images onto clothing. Various transfer sizes are available, from common A4 and A3 formats to more specialized, custom dimensions that cater to specific garment shapes and sizes. This discussion on how to determine the appropriate transfer sizes will assist designers in creating impactful instructions for their custom DTF transfers. By ensuring the dimensions match the intent and design, you’ll elevate the quality of your garment transfer printing.

Understanding DTF Transfer Dimensions

When you’re venturing into the realm of Direct-to-Film (DTF) transfers, understanding the various dimensions available is critical to ensuring the success of your projects. DTF transfer dimensions fundamentally dictate how your designs will appear on fabric and can make a significant difference in the final outcome. Most commonly used sizes include A4 and A3 formats, but these standard measurements are often just the tip of the iceberg. Depending on your specific needs, you might find that exploring custom DTF transfer sizes becomes necessary to achieve the best results.

Custom sizes can be particularly beneficial when you are dealing with unique products such as oversized hoodies or sports jerseys. Imagine wanting to create a bold graphic for a special event or promotional product; opting for a custom dimension allows you to showcase your design without restriction. Therefore, it’s crucial to assess your project’s requirements early in the design phase to choose the most appropriate DTF transfer dimensions.

Choosing the Right DTF Transfer Sizes

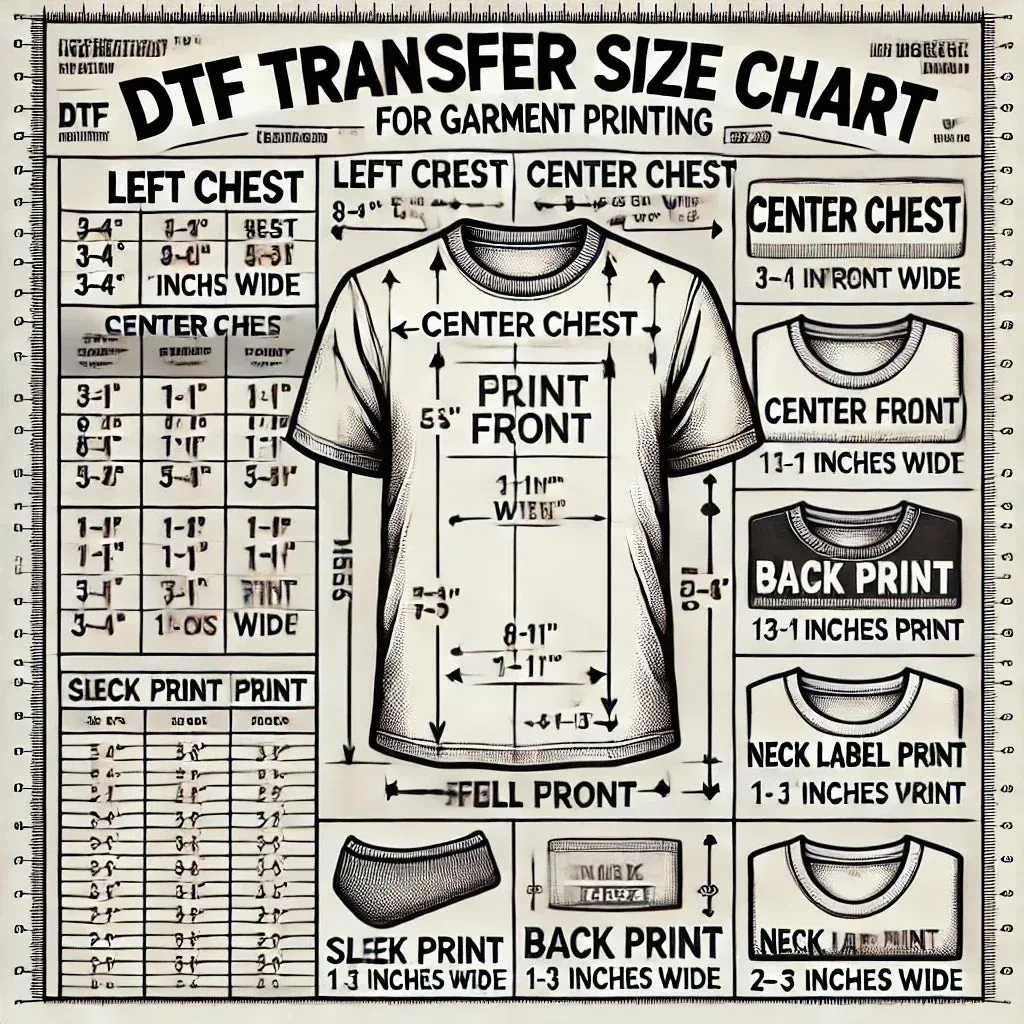

Selecting the right DTF transfer size may seem daunting, but there are effective strategies to simplify the decision-making process. First, consider the type of garment and the target audience. For instance, standard DTF transfer sizes like A4 work well for basic t-shirt designs. However, configurations can change drastically in other contexts, such as hoodies or jackets, where space for larger, eye-catching graphics is available. Assessing the garment type is essential as it directly influences the impact of your design.

Another factor to consider is how your selected dimensions will match with your print design’s resolution and aspect ratio. A high-resolution image with a dimension that complements the garment’s size ensures a crisp and clear transfer. If you’re unsure how to choose DTF dimensions, it can be useful to create mock-ups of your design on the intended apparel. This hands-on experience lets you visualize potential outcomes and helps reaffirm the best size for your DTF projects.

Maximizing Quality in DTF Transfer Designs

The quality of a DTF transfer hinges not only on dimensions but also on the design’s preparation. Ensuring that your artwork is created at a high resolution of at least 300 DPI will result in transfers that are vibrant and visually appealing, whether you’re using standard or custom sizes. Additionally, paying attention to the aspect ratio is crucial for maintaining visual integrity across different sizes. Designs that undergo resizing must keep their proportions consistent, or else it can lead to distortion or loss of detail.

Moreover, testing your design on various transfer sizes allows you to see how it appears in different scenarios. This experimentation phase is invaluable as it broadens your understanding of how aspects like scale affect the final product. Whether you are producing custom DTF transfers or using standard sizes, maintaining high standards for quality and resolution is a must.

Printer Specifications and DTF Transfer Sizes

Before you dive into DTF printing, it’s imperative to understand the capabilities and limitations of your printing equipment. Different DTF printers will have set maximum print sizes that can drastically affect your design choices. For example, if you are limited to a maximum print size of 18 inches, creating oversized graphics that exceed that limit would result in disappointment or additional costs. Knowing your printer’s specifications allows for smarter decisions and less waste.

Additionally, being aware of transfer film dimensions is equally important. Films that are either too large or small can affect the adherence and quality of the final product. Aligning your design’s dimensions with the appropriate transfer film ensures a seamless application, enhancing the overall quality of your DTF transfers. When planning a project, creating a checklist of these specifications can guide you in making optimal choices, thus leading to impressive results.

Best Practices for DTF Transfer Projects

Learning from the experiences of seasoned DTF users can significantly improve your printing endeavors. A common piece of advice offered by veterans in the field is to start with standard sizes. Engaging with simple dimensions allows beginners to get accustomed to the intricacies of DTF printing without feeling overwhelmed by the complexities of custom specifications. As projects become more intricate, transitioning to custom DTF sizes becomes a natural progression.

By experimenting with varying sizes, creators can unlock a new level of creativity. Every apparel piece offers unique opportunities for design; using custom dimensions enables personalization that meets both aesthetic and functional needs. Over time, this exploration of different DTF sizes can inspire innovative designs while optimizing the impact of visuals on different garments.

Current Trends in DTF Printing Customization

As the DTF printing market evolves, the customization trend is prominent, driven by consumer demand for personalized products. Brands are increasingly offering tailored options, allowing customers to choose DTF transfer dimensions that suit their specific desires. This flexibility in choice not only enhances customer satisfaction but also helps businesses differentiate themselves in competitive marketplaces. By mastering the adaptation of standard sizes into custom offerings, you can cater effectively to a variety of client needs.

Furthermore, the shift toward customization aligns with the creative solutions businesses are seeking. By taking standard DTF sizes and creatively adapting them, companies can keep their offerings fresh and exciting. Staying attuned to these trends will enable print businesses to sustain their unique identity while fulfilling consumer desires for individuality and personal expression in their garments.

Frequently Asked Questions

What are the standard DTF transfer sizes used in garment transfer printing?

Standard DTF transfer sizes typically include formats like A4 and A3. These sizes work well for most projects, but for specialized garments or unique designs, custom sizes can provide a better fit.

How do I choose the right DTF transfer dimensions for my project?

When choosing DTF transfer dimensions, consider the type of garment and design aesthetic. Smaller designs are suitable for t-shirts (10-12 inches wide), while larger graphics work great for hoodies and jackets.

What are the implications of using custom DTF transfer sizes?

Custom DTF transfer sizes allow for tailored solutions to meet specific needs, enhancing the visual appeal of unique designs on various apparel. Experimenting with sizes can yield innovative results for your projects.

Why is resolution important when creating DTF transfers?

High resolution is crucial for DTF printing as it ensures clarity and vibrancy. Preparing designs at 300 DPI helps maintain quality across all DTF transfer dimensions, regardless of size.

What printer capabilities should I consider when selecting DTF transfer sizes?

It’s important to know your printer’s maximum print size limitations before designing. If your DTF printer can only handle transfers up to 18 inches, make sure your designs adhere to this dimension to avoid errors.

How can I ensure the best results with my DTF transfer printing?

To achieve the best results, start with standard DTF transfer sizes, maintain a consistent aspect ratio in your designs, and align your transfer films with the dimensions you’ve selected to prevent issues during the printing process.

| Key Points | Details |

|---|---|

| Understanding DTF Transfer Sizes | Typical sizes are A4 and A3; custom sizes for specific garments. |

| Standard Sizes | Use standard for simple projects; custom for unique designs. |

| Application Specificity | Small designs fit t-shirts (10-12 inches), larger for hoodies. |

| Design Considerations | High resolution (300 DPI) is crucial for clarity and quality. |

| Aspect Ratio | Maintain proportions to avoid distortion during resizing. |

| Printing Technology and Limitations | Know printer’s max print size to prevent wasted materials. |

| Transfer Film Dimensions | Choose transfer film size to match your design dimensions. |

| User Experiences and Recommendations | Start with standard sizes to learn the process. |

| Experimentation | Once basics are known, experiment with custom sizes. |

| Recent Trends | Customization is on the rise in DTF printing. |

| Personalization and Market Demand | DTF printing is attractive for personalized products. |

| Creative Solutions | Adapting sizes creatively helps businesses stay innovative. |

Summary

In conclusion, understanding the dimensions for DTF transfer dimensions is crucial for the success of your textile printing projects. It encompasses recognizing standard sizes, maintaining high design quality, and being aware of the specific limitations of your printing technology. By mastering these elements, businesses can not only enhance their product offerings but also stay competitive in a market that increasingly values customization and innovation. As the popularity of DTF printing continues to grow, the importance of effectively utilizing DTF transfer dimensions will only become more pronounced.