Introducing the DTF Gangsheet Builder, a revolutionary tool designed to elevate the world of custom garment printing. In an industry constantly evolving with consumer demands, finding the best printing methods is crucial for business success. DTF, or Direct to Film printing, stands in contrast to traditional printing techniques like screen printing and direct-to-garment options, providing unique advantages that cater to modern needs. By understanding DTF printing vs screen printing, you can make informed choices about your production processes. As we delve deeper, we’ll explore the nuances of DTF vs traditional methods, helping you decide which is the right fit for your garment projects.

The DTF Gangsheet Builder is transforming how custom apparel is produced, showcasing the latest in printing technology. As businesses grapple with choosing optimal methods, comparisons between DTF printing and more established practices come into play, revealing the strengths and weaknesses of each approach. With a focus on custom designs, this innovative solution offers an appealing alternative to legacy techniques. By examining traditional versus contemporary printing methods, businesses can better align their production capabilities with market demands. Thus, the conversation around the effectiveness of DTF approaches versus traditional strategies becomes imperative for anyone looking to thrive in garment printing.

Understanding DTF Gangsheet Builders

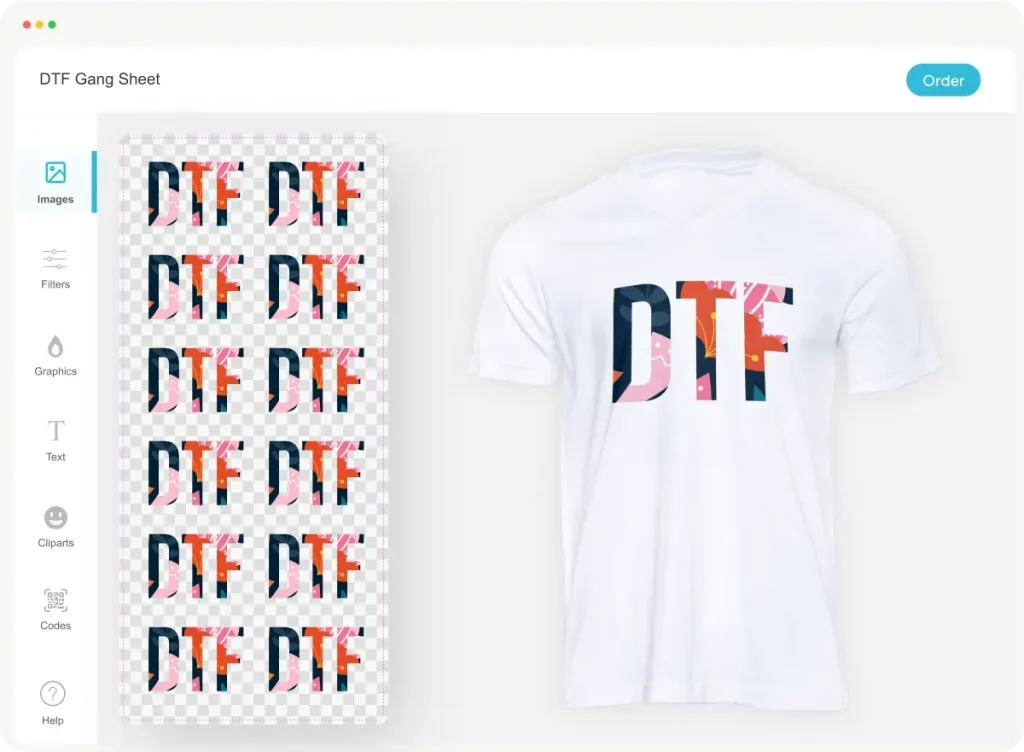

DTF Gangsheet Builders are revolutionary tools in the garment printing industry. They allow users to create multiple designs on a single sheet, significantly improving efficiency for custom orders. By utilizing DTF printing technology, designers can print vibrant colors and intricate patterns on high-quality film, which is then transferred onto a variety of fabric types. This method not only streamlines the printing process but also caters to businesses looking for cost-effective solutions for small runs.

Moreover, the versatility of DTF Gangsheet Builders is unmatched, as they can print on cotton, polyester, and blends with ease. This adaptability makes them an optimal choice for businesses that require diverse fabric printing solutions. Therefore, as enterprises embrace customization in apparel, DTF technology stands out as a parallel to traditional methods, offering innovative capabilities to meet evolving market demands.

DTF Printing vs. Screen Printing: A Comparative Analysis

When contrasting DTF printing with traditional screen printing, notable differences emerge. DTF technology excels in producing complex designs with rich color features and finer details that might be challenging to achieve with screen printing. Screen printing, while a staple in the industry for its reliability and cost-effectiveness on high volumes, tends to be limited in color variation and intricacy. Thus, for custom garment printing that requires vibrant visuals, DTF proves to be a superior alternative.

However, screen printing has its strengths, particularly in longevity of prints, making it a preferred option for bulk orders where durability is crucial. The setup costs for screen printing can be substantial, but for large-scale runs, the cost per unit decreases significantly. In contrast, DTF printing is more advantageous for smaller runs due to its lower setup costs, making it an appealing choice for those who prioritize versatility and detailed designs over massive production.

The Best Printing Methods for Custom Orders

Choosing the best printing method for custom orders depends on various factors, including the desired outcome, volume of production, and material used. DTF printing has emerged as a leading method for small and medium-sized enterprises seeking personalized printing solutions, thanks to its cost-effectiveness and flexibility. Many businesses find that the ability to print on different fabrics without compromising quality gives DTF a significant edge over traditional methods.

On the contrary, businesses with high volume needs and less variation in design often lean towards traditional methods such as screen printing. This classic approach has been refined over the years to deliver high-quality prints with excellent durability, especially on cotton fabrics. Ultimately, the best method will depend on balancing project requirements against production capabilities, allowing brands to choose the printing process that aligns with their operational objectives.

Durability Comparison: DTF vs. Traditional Methods

Durability is a critical factor to consider when comparing DTF and traditional printing methods. DTF printing is known for producing vibrant and finely detailed images, but its longevity can sometimes fall short of what screen printing offers. Screen printing has been trusted for years due to its robust nature, especially in garments designed for heavy use. Users appreciate that traditional prints can withstand repeated wash cycles and rigorous wear without losing their vibrancy.

In contrast, while DTF advances continuously improve its durability, concerns about fading over time remain. This is especially true if garments undergo heavy washing or exposure to harsh conditions. For industries that demand high durability, traditional printing methods may still prove to be the go-to option. Many customers prefer familiar and tested solutions to ensure their garments remain in top condition even after numerous uses.

Evaluating Production Costs in DTF Printing

The cost-effectiveness of DTF printing makes it an intriguing option for businesses that require flexibility and precision in smaller production batches. Compared to traditional methods, which may require high minimum orders, DTF fits the needs of entrepreneurs and smaller businesses looking to produce custom designs without the burden of hefty upfront costs. This is particularly appealing for startups and custom apparel shops that depend on offering unique, personalized items to their clientele.

Moreover, the operational costs associated with DTF Gangsheet Builders can be more favorable, especially when considering lower setup expenses for smaller orders. By minimizing waste and allowing for immediate adjustment in design, DTF helps to enhance overall profitability and reduces any financial risks associated with overproduction. Thus, businesses are finding DTF an innovative alternative that streamlines their processes while bolstering their capability to adapt to customer demands rapidly.

Market Trends Favoring DTF Technology

Recent market trends indicate a growing preference for DTF printing among businesses focused on customization and rapid turnaround times. As consumer preferences evolve and demand for personalized apparel increases, DTF technology is positioned to meet these requests effectively. Its ability to handle a myriad of fabric types, coupled with its quality outputs, puts it at the forefront of garment printing advancements.

Additionally, as more businesses realize the potential of DTF printing for creating unique designs with less bulk inventory, it becomes imperative for traditional printers to adapt. This shift towards DTF aligns with the broader industry movement toward on-demand production, reflecting an overarching inclination towards sustainability and efficiency. With these trends solidifying, DTF printing continues to gain traction in the competitive landscape of garment production, challenging conventional methods.

Frequently Asked Questions

What are the main benefits of using the DTF Gangsheet Builder over traditional printing methods?

The DTF Gangsheet Builder offers several advantages over traditional printing methods. It is cost-effective for small runs, enables vibrant color and detail replication, and can print on a variety of fabrics. This versatility makes it ideal for custom garment printing, addressing businesses’ needs for diverse designs and material compatibility.

How does DTF printing compare to screen printing in terms of setup costs and efficiency?

DTF printing generally involves lower setup costs for small orders compared to screen printing, which often has high initial setup expenses due to screen creation. Additionally, DTF printing allows for quicker prototyping and testing, making it a flexible option for custom garment printing, whereas screen printing is more efficient for large volume runs.

Are the prints generated by DTF Gangsheet Builders as durable as those produced by traditional printing methods?

While DTF prints can offer vibrant colors and intricate designs, traditional methods like screen printing are often deemed more durable. Screen printing prints tend to withstand multiple washes better, maintaining their color and integrity over time, which can be a crucial consideration for long-lasting custom garments.

What types of fabrics can be used with DTF Gangsheet Builder technology?

DTF Gangsheet Builder technology is highly versatile and can be used on various fabric types, including cotton, polyester, and blends. This capability allows businesses to cater to a wide range of customer preferences and applications, making it a preferred choice in custom garment printing.

What should businesses consider when choosing between DTF printing and traditional methods?

When choosing between DTF printing and traditional methods, businesses should assess factors like startup costs, production volume, print durability, and the complexity of designs. DTF printing is excellent for lower volume and custom designs, while traditional methods like screen printing are better suited for high-volume, durable prints.

Is DTF printing gaining popularity over traditional printing methods in the garment industry?

Yes, DTF printing is increasingly gaining popularity due to its cost-effectiveness, flexibility, and ability to produce high-quality prints for a wide variety of fabrics. As market trends shift towards personalized and low-volume production, DTF technology is becoming a preferred choice for custom garment printing.

| Key Points | DTF Gangsheet Builder | Traditional Printing |

|---|---|---|

| Definition | Prints designs on film and heat transfers to fabric. | Includes techniques like screen printing and DTG. |

| Versatility | Can be used on a variety of fabrics (cotton, polyester, blends). | Limited to specific materials, may not achieve the same detail. |

| Cost-Effectiveness | Ideal for small runs, no high minimum orders required. | Higher setup costs for smaller orders due to equipment needs. |

| Color and Detail | Excellent for vibrant colors and intricate designs. | Good, but may not match DTF in detail replication. |

| Durability | May face issues with fading over time. | Highly durable, especially screen printing options. |

Summary

DTF Gangsheet Builder offers a revolutionary approach to garment printing, allowing businesses to explore vibrant and versatile design possibilities. As the choice between DTF Gangsheet Builders and traditional printing methods becomes crucial, understanding their respective benefits and limitations is key. DTF printing excels in producing intricate designs economically for smaller runs, appealing to a market increasingly focused on customization. In contrast, traditional printing remains a reliable option when durability and high-volume efficiency are paramount. Ultimately, the best choice will hinge on specific business needs and goals in the dynamic apparel printing landscape.