DTF Gangsheet Builder Techniques have emerged as a game-changer in the garment decoration industry, revolutionizing how designs are created and implemented. This innovative approach to Direct-to-Film printing allows businesses to maximize their design potential while reducing waste. The DTF printing process not only enhances transfer efficiency but also offers designers unparalleled creative freedom when working with gangsheet design methods. By focusing on strategic layout planning, color management, and effective software solutions, companies can streamline their production processes and create vibrant, high-quality prints. In this guide, we’ll dive deeper into these techniques, providing valuable insights into optimizing your workflow and design outcomes.

Often referred to as Direct-to-Film gangsheet techniques, this innovative method within garment decoration allows for a highly efficient approach to creating intricate designs. By utilizing the DTF printing method, decorators can take full advantage of film transfers, leading to significant enhancements in transfer efficiency. Moreover, the gangsheet layout facilitates the arrangement of multiple designs on a single sheet, which not only reduces material waste but also accelerates production times. This comprehensive guide will explore a variety of key strategies and best practices to optimize garment decoration techniques, ensuring that your designs maintain their vibrancy and quality even under high-volume demands.

The Revolutionary Impact of DTF Printing on Garment Decoration

DTF printing has significantly transformed the garment decoration industry by streamlining the way designs are created and applied to fabric. This innovative technology allows for the direct application of vibrant inks onto a specially coated film, which is then transferred onto various types of fabrics. The beauty of DTF printing lies in its ability to reproduce intricate designs with stunning clarity and colors, making it a preferred choice for both small and large-scale production. Because of its versatility, DTF has opened new avenues for customization, catering to modern consumer demands for personalized apparel.

In addition to its impressive print quality, DTF printing offers a range of practical benefits. One of the most notable advantages is its efficiency in producing garments. Businesses can print multiple designs on a single transfer, significantly reducing material waste and production time. This capability not only lowers costs but also allows garment decorators to respond quicker to market trends and customer requests. Consequently, DTF printing is not just a trend; it’s a pivotal technology that has reshaped the landscape of garment decoration.

Exploring DTF Gangsheet Builder Techniques

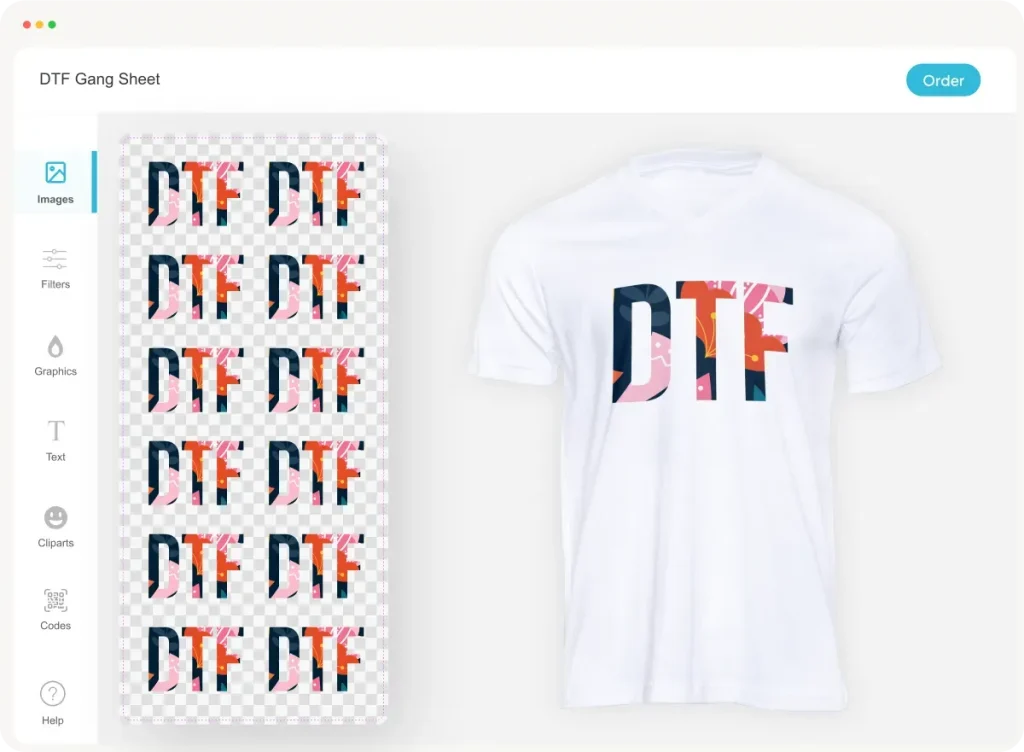

The DTF gangsheet builder technique is a game-changer for businesses aiming to maximize production efficiency. By arranging multiple designs onto a single DTF film transfer sheet, decorators minimize waste and streamline their workflows. This method is advantageous when fulfilling bulk orders, as it allows for various designs to be printed simultaneously, significantly enhancing productivity. The gangsheet approach also affords designers the opportunity to explore how different designs interact, leading to visually harmonious collections.

Moreover, implementing gangsheet techniques requires a keen understanding of layout and spacing. Utilizing specialized software, designers can meticulously plan the arrangement of different graphics to ensure that they fit well together on the transfer sheet. Correctly balancing these elements minimizes the risk of overlapping or cutting off critical design features during the transfer process. In essence, mastering gangsheet builder techniques can elevate the quality and efficiency of garment decoration to new heights.

Maximizing Design Potential with Optimal Layout Planning

Layout planning is crucial when utilizing DTF gangsheet builder techniques for garment decoration. Effective planning not only ensures that each design is aesthetically appealing but also maximizes the use of transfer film. By strategically placing designs within the printable area, decorators can create a cohesive sheet that minimizes wasted material, leading to lower costs and improved efficiency. Utilizing software that specializes in gangsheet layout can significantly simplify this process, allowing for intuitive arrangement adjustments.

A successful layout plan should consider factors such as spacing, alignment, and color flow between designs. The right positioning not only enhances the visual appeal of the final product but also facilitates easier handling during the transfer process. Therefore, investing time in optimal layout planning can lead to substantial improvements in both production speed and the quality of the finished garments. Designers who prioritize this step find that their ability to reproduce intricate, high-quality prints increases exponentially.

Essential Color Management in DTF Printing

Color management plays a vital role in achieving the desired outcomes in DTF printing, making it an essential aspect of the gangsheet builder technique. Successful garment decoration relies on consistent and accurate color replication; thus, using color profiles that align with the specifics of DTF printing is crucial. This ensures that the colors printed on the transfer film closely match the original design, preserving the integrity of the artwork across various fabric types.

Choosing the right inks that are compatible with both the film and the fabric is also part of effective color management. Using inappropriate inks can lead to issues such as poor adherence and inaccurate colors once the transfer is applied. By standardizing the color profiles and conducting pre-production tests, designers can enhance their output’s quality and reliability. This careful consideration in the color management process not only elevates the overall print quality but also boosts customer satisfaction.

Streamlining Design Preparation for Optimal Results

Effective design preparation is critical when utilizing DTF gangsheet builders for garment decoration. Preparing vector-based designs allows for flexibility and clarity, as these types of files can be resized without losing quality. This aspect is especially important when creating transfers for different fabric dimensions, ensuring that every design maintains its integrity. Moreover, designers need to be aware of the recommended resolution and dimensions for the fabric types they intend to print on to meet industry standards.

Additionally, software tools available for DTF printing offer features that make design preparation more efficient. With capabilities like mock-up creation and easy adjustments to design parameters, these tools can save valuable time during production. Properly preparing designs not only contributes to the final quality of garments but also aids in reducing errors that could result in costly reprints. Thus, emphasizing meticulous design preparation is a key factor in achieving superior print results and enhancing overall productivity.

Exploring Software Solutions for DTF Gangsheet Efficiency

Software solutions dedicated to DTF printing play a pivotal role in enhancing efficiency during the gangsheet design process. Programs such as Adobe Illustrator are widely used for their robust feature set, allowing designers to create and manipulate intricate designs efficiently. In addition, specialized DTF software provides tools tailored specifically for gangsheet layouts, enabling users to visualize and organize multiple designs easily. This streamlined approach ensures that the artwork correlates effectively with intended print requirements.

Furthermore, the integration of software solutions into the DTF printing workflow can significantly reduce the time spent on design modifications. Features like drag-and-drop functionalities and preset layout templates enable designers to experiment with arrangements fluidly. As a result, businesses can adapt quickly to customer demands while maintaining high-quality output and minimizing production delays. Investing in the right software tools proves essential for any garment decoration venture looking to thrive using DTF gangsheet builder techniques.

Frequently Asked Questions

What are DTF gangsheet builder techniques?

DTF gangsheet builder techniques refer to the method of efficiently arranging multiple designs on a single Direct-to-Film (DTF) transfer sheet. This approach minimizes material waste, optimizes production time, and allows for cost-effective bulk printing, ensuring various designs can be printed simultaneously without sacrificing quality.

How does the DTF printing process enhance garment decoration?

The DTF printing process enhances garment decoration by producing high-quality transfers that adhere to a variety of fabric types. This technique allows for vibrant colors and intricate designs that maintain their richness, offering flexibility for mass customization, which is crucial for meeting diverse consumer preferences.

What benefits do gangsheet techniques provide in DTF printing?

Gangsheet techniques in DTF printing provide multiple benefits including significant cost savings, increased production efficiency, and the ability to create cohesive collections of designs. By arranging multiple graphics on a single sheet, businesses can fulfill large orders while reducing material and labor costs.

What is the importance of color management in DTF gangsheet builder techniques?

Color management is vital in DTF gangsheet builder techniques as it ensures that printed colors align with design expectations. Utilizing appropriate color profiles and compatible inks helps avoid issues with adherence and color fidelity, thus maintaining the quality and vibrancy of the final garment decoration.

How can I prepare my designs for DTF printing using gangsheet methods?

To prepare your designs for DTF printing using gangsheet methods, ensure they are vector-based for scalable clarity, and research the appropriate dimensions and resolutions for the fabrics you are working with. This preparation, alongside optimal layout planning using software, enhances the quality of the transfers.

Which software is best for creating gangsheet designs in DTF printing?

Software like Adobe Illustrator and specialized DTF design programs are ideal for creating gangsheet layouts. These tools offer features tailored to gangsheet building, such as rapid mock-up capabilities and alignment guides, streamlining the design process to enhance efficiency and output quality.

| Section | Key Points |

|---|---|

| Introduction | DTF printing technology enhances garment design processes, emphasizing layout planning and design preparation. |

| Overview of DTF Technology | Produces high-quality fabric transfers, suitable for various materials, ensuring vibrant designs. |

| Benefits of DTF Printing | Versatile, durable, and efficient, making it suitable for bulk customization. |

| Understanding Gangsheet Techniques | Arranging multiple designs on one transfer sheet reduces waste and optimizes time. |

| Creating a Gangsheet | Select designs and arrange them mindfully using software to maintain spacing. |

| Key Techniques to Maximize Designs | Focus on layout planning, color management, design preparation, and software solutions. |

| Benefits of DTF Gangsheet Builders | Cost-effective, increases production efficiency, and accommodates various fabrics. |

| Resources for Further Learning | Refer to Printwear Magazine, Avery.com, and YouTube for insights and tutorials. |

Summary

DTF Gangsheet Builder Techniques are vital for anyone in the garment decoration industry aiming to elevate their design capabilities. By implementing strategic planning in layout, fine-tuning color management, and leveraging specialized software, designers can dramatically enhance production workflows while ensuring high-quality outcomes. This approach not only reduces costs but also propels businesses to meet the growing demands of customization in today’s marketplace. Continuous education and adaptation of the latest practices are crucial for achieving success in the evolving landscape of garment decoration.