DTF transfer by size is transforming how brands approach apparel decoration, aligning artwork with garment dimensions to deliver vibrant, durable transfers that look right on wear and reduce setup guesswork from the start, while helping shops scale designs across multiple sizes with confidence and clarity for operators, customers, and press technicians alike. Using a DTF transfer size guide helps designers translate chest widths, back lengths, sleeve contours, and neck opening shapes into practical print areas, while considering garment size considerations, fabric behavior, ink interaction, and how the print may shrink or stretch in wear, wash cycles, flexing, and varying fabric blends. Pair that planning with reliable prepress DTF alignment checks, color management, and proven DTF printing tips to safeguard alignment, avoid edge bleed, preserve margins, and ensure tonal accuracy across foregrounds and shadows before any transfer ever meets the fabric. This proactive sizing mindset standardizes workflow across product families, reduces misprints, fosters repeatable calibrations, and supports consistent results whether you print full-front art, a double-panel design, or smaller left-chest marks on a range of brands, fabrics, and customer preferences. When teams consistently align the transfer size with garment dimensions early in the process, customers enjoy better fit, crisper imagery, faster turnarounds, and fewer post-purchase surprises, improving satisfaction, repeat business, and overall brand reputation.

From a different angle, practitioners talk about size-aware transfer strategies that map artwork to the garment print area by considering fabric type, placement, and how body movement affects perceived scale. This approach relies on terms like print-area mapping, garment flare, and placement precision, all rooted in LSI concepts that connect related ideas such as sizing, alignment, and color management. Other phrases you hear include artwork-to-textile sizing, dimension-driven layout, and alignment-first workflows that emphasize predictable outcomes across shirt cuts, hoodies, and specialty fabrics. By focusing on related signals—centerline, margins, shrinkage allowances, and test proofs—teams build resilient templates that translate designs into apparel with confidence.

DTF Transfer By Size: Aligning Print Area with Garment Size

DTF transfer by size is the practice of selecting a transfer image size that mirrors the garment’s actual dimensions, print area, and intended placement. By aligning the transfer size with the garment, you improve alignment, color accuracy, and overall customer satisfaction. This approach also helps minimize edge artifacts and ensures consistency across production runs.

To implement this effectively, use the DTF transfer size guide to map artwork to typical garment dimensions, predict how the print may shrink or stretch, and establish safe margins from seams and edges. When paired with garment size considerations, this method creates a repeatable workflow from prepress through curing, reducing misalignment and rejects.

Reading and Applying the DTF Transfer Size Guide for Consistent Results

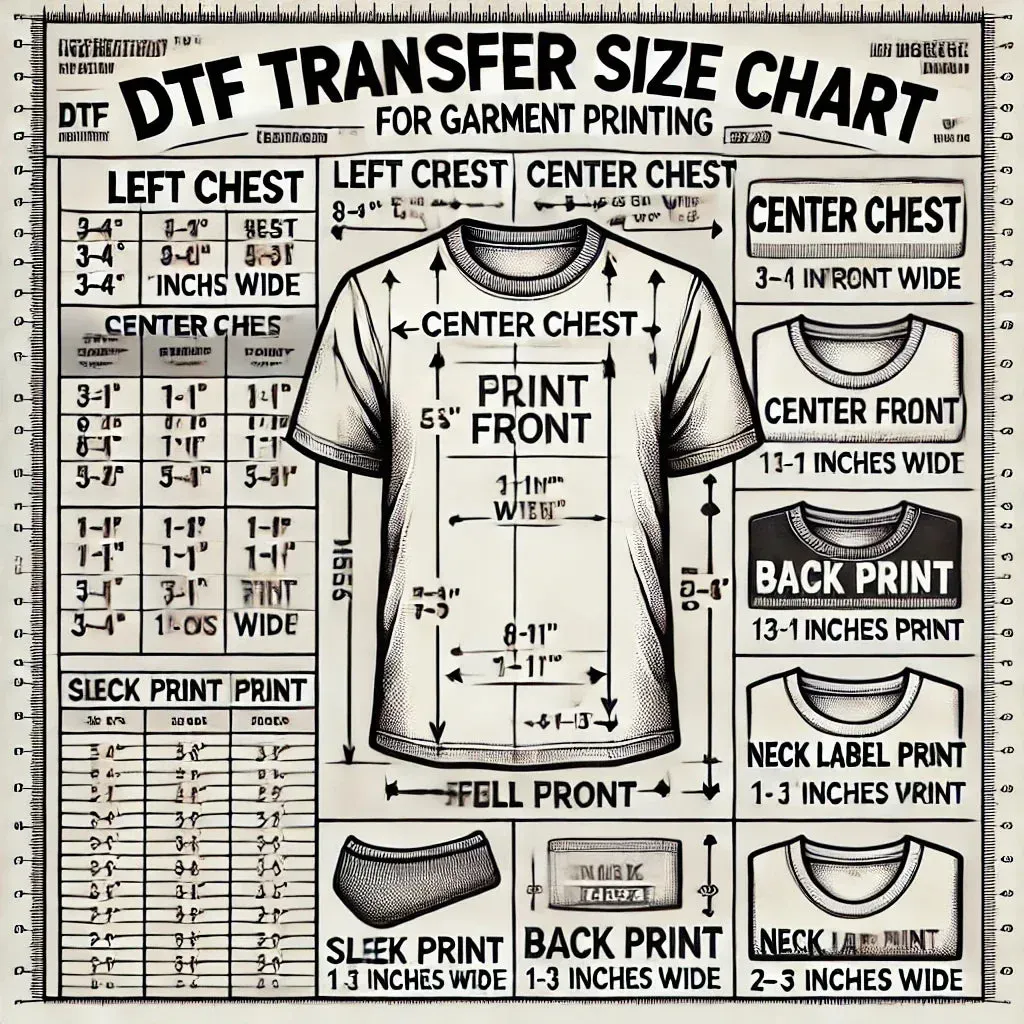

A well-used DTF transfer size guide helps designers translate digital art into real-world crops across multiple garment sizes. It clarifies how much print area you should allocate for chest designs, full-front artwork, or small left-chest marks, and how shrinkage may affect final appearance. Understanding this guide is essential for predictable outcomes.

Apply the guide by measuring target garment dimensions, calibrating with samples, and validating print sizes on test garments. Incorporate DTF printing tips such as testing ink density, alignment, and color transfer during prepress alignment to ensure the final result matches expectations for each size category.

Garment Size Considerations: How Dimensions Drive Design Decisions

Garment size considerations cover brand variances, fabric weights, and how different cuts influence print placement. A design that looks proportional on a size M tee may appear oversized on a small or cramped on an XL. Acknowledging these differences helps you tailor print area and margins to each size.

Practical calibration involves collecting size-specific measurements, obtaining samples from several brands, and validating the design across S, M, L, and XL. This ensures the transfer remains visually balanced across the entire size range and aligns with customer expectations.

DTF Printing Tips for Color, Adhesion, and Edge Integrity

DTF printing tips cover ink density, color management, and adhesion to a variety of fabric types. Adjusting ink load and underbase planning can preserve vibrancy on dark fabrics, while maintaining edge integrity requires mindful margins and accurate prepress setup.

Color tuning, test prints, and center alignment checks are essential components of a reliable workflow. By integrating these tips early—during prepress alignment—you reduce surprises during curing and preserve the intended appearance across different garment colors and textures.

Prepress Alignment: The Cornerstone of Accurate Transfers

Prepress alignment ensures the design is centered along the garment’s vertical axis and aligned with seams, collars, and plackets. When you size by garment, you should verify alignment with a center reference before applying the transfer to fabric.

Use center guides or a printed ruler on the transfer film, compare to the garment’s plumb line, and perform a dry run to confirm center placement. Consistent prepress alignment reduces misplacement and helps maintain the integrity of the final appearance in every size.

Validation and Quality Control: From Mockups to Mass Runs

Validation starts with full-size mockups on sample garments across sizes to confirm alignment, print area, and color fidelity. This is where DTF printing tips—like test prints and controlled curing—shine, giving you confidence before committing to a run.

Quality control relies on a standardized sizing chart and operator training to ensure consistency across batches. Regular calibration, shrinkage consideration, and a strict prepress alignment checklist help minimize rejects and deliver reliable results for every order.

Frequently Asked Questions

What does DTF transfer by size mean and why are garment size considerations important?

DTF transfer by size means selecting a transfer image size that matches the garment’s dimensions, print area, and intended placement. Garment size considerations help ensure the design stays proportional across sizes, improves alignment, and preserves color fidelity. Use the DTF transfer size guide to map artwork to typical garment dimensions and account for shrinkage, seams, and fabric behavior.

How can I use the DTF transfer size guide to determine the print area for different garment sizes?

Refer to the DTF transfer size guide to map artwork to typical garment dimensions. Start by measuring the garment’s chest width; decide if you want a chest, full-front, or small-mark print; scale the design to about 60–75% of chest width for adult shirts, and add safe margins to avoid edge bleed. Validate with samples across sizes to confirm fit and alignment.

What are essential DTF printing tips to maintain color and alignment when the transfer size varies by garment size?

Follow practical DTF printing tips: test prints across sizes, check prepress alignment, calibrate color for each fabric, and factor shrinkage into the initial design. Maintain a sizing chart and use mockups to ensure consistent color and placement across sizes.

Why is prepress alignment critical for size-based transfers and how can I ensure correct alignment?

Prepress DTF alignment is critical for predictable results. Align the design with the garment’s centerline and edges, and print a center guide on the transfer film before applying. Use garment plumb lines and mockups to verify center positioning across sizes.

How should I scale and position a design for various garment sizes to keep proportion and readability?

Scale designs to a consistent percentage of the garment’s chest width (roughly 60–75% for many adult shirts) and adjust for brand variations and fabric. Maintain aspect ratio, use safe margins, and validate with test prints to ensure readability on smaller sizes. Refer to the DTF transfer size guide when in doubt.

What are common mistakes when applying DTF transfers by size and how can I avoid them?

Common mistakes include ignoring garment size variations, skipping margins, improper prepress alignment, and not accounting for shrinkage, or inconsistent print area. Avoid these by using a standardized sizing chart, conducting tests across sizes, and performing a prepress alignment check before curing. Consistent use of DTF transfer by size concepts helps reduce errors.

| Aspect | Key Points |

|---|---|

| What is DTF Transfer By Size? | Definition: aligning transfer image size with garment dimensions, print area, and placement; measure, plan, and test to maximize visual impact while staying within print area percent and safe margins; reduces misalignment and edge artifacts; ensures consistent results. |

| Role of a Size Guide | DTF transfer size guide maps artwork to typical garment dimensions; prevents oversized designs on small sizes and cramped ones on large sizes; helps predict shrink/stretch and enables a predictable workflow from prepress through curing. |

| How to Decide the Right Size (Step-by-Step) | 5 steps: 1) assess garment and size range; 2) define print area and safe margins; 3) use garment width as guide for design width (e.g., 60–75% of chest width for adults); 4) account for shrinkage and stretch; 5) validate with a test print across multiple sizes (S, M, L, XL). |

| Practical Guidelines by Garment Type | Adult T-Shirts: chest print 10–12 in; full-front 12–14 in; height 12–15 in. Hoodies: width 11–13 in for full-front; taller height if design extends toward upper chest. Kids: 4–6 in wide. Specialty fabrics: may require larger print areas on darker or textured fabrics; apply color tuning and underbase considerations. |

| Calculating Final Print Size: A Quick Example | Example: chest logo on size M tee with chest width 20 in. 60% width = 12 in. Subtract 0.5 in for margins → 11.5 in width. Height should match aspect ratio (square = 11.5 in; 1:1.2 ratio ≈ 13–14 in). Verify alignment with center guide. |

| Role of Prepress Alignment and Color Management | Prepress alignment ensures centering along the vertical axis; print a small center guide before applying to fabric. Color management may require adjusting ink density and performing calibration-like tests; run print tests to map colors to garment color and fabric texture. |

| Common Mistakes and How to Avoid Them | Ignoring garment size variations; overlooking margins; skipping prepress alignment checks; failing to account for shrinkage; inconsistent print area across batches. |

| Tips and Resources for Keeping the Workflow Efficient | Maintain a simple standard size chart; create a quick-reference sizing cheat sheet; use a mockup template with a ruler; regularly calibrate curing settings for consistent adhesion and color fidelity. |