Understanding DTF transfer size is vital to achieving outstanding results in the world of Direct-to-Film (DTF) printing. This innovative printing technique allows for vibrant and durable designs to be transferred onto various substrates, but the size of the transfer can significantly affect the outcome. Achieving optimal print sizes ensures that intricate details are maintained and the quality isn’t compromised, which is essential for creating visually stunning products. In this introductory article, we will explore fundamental DTF printing tips and the relationship between transfer size and print quality. Join us as we dive deep into this crucial topic, ensuring you have the insights needed to enhance your DTF printing endeavors.

When discussing the dimensions of Direct-to-Film transfers, we are delving into a critical aspect of the printing process that can make or break the final result. Whether referred to as transfer dimensions, design scaling, or optimal sizing, it’s clear that these factors play a significant role in the quality and effectiveness of prints. As we explore various DTF printing techniques, we will uncover how adhering to proper transfer sizes not only improves the aesthetic appeal but also contributes to the durability and adherence of prints. By applying the right DTF printing strategies, creators can ensure that their designs retain clarity and vibrancy, ultimately leading to superior products that meet client expectations.

Understanding DTF Transfer Size and Its Impact

DTF transfer size is a crucial aspect that significantly affects the overall quality of the print. Selecting the correct size for your DTF transfers not only ensures that designs are displayed as intended but also enhances their durability and visual appeal. Larger DTF transfers can express more intricate details, but this comes at the risk of compromising adhesion and clarity if not executed with precision. Therefore, understanding how to optimize transfer sizes is essential for achieving high-quality results.

Getting the DTF transfer size right is also linked to the material you are printing on. Different fabrics react differently to various sizes and designs. For instance, oversized prints on lightweight fabrics can lead to warping or bubbling, detracting from the print’s quality. It’s critical to conduct trials to determine the optimal size for each specific fabric type and ensure that your designs maintain their integrity and vibrancy, regardless of the transfer dimensions.

Achieving Optimal Print Sizes for DTF Printing

Optimal print sizes in DTF printing refer to the dimensions that create a harmonious balance between design detail and print quality. When prints are resized for different garments, adhering to the design’s proportional integrity is essential. If you scale a design incorrectly, it can lead to a loss of detail, compromising the artistry of the print. Hence, before finalizing your output sizes, it’s advisable to run test prints to see how different dimensions translate in a real-world context.

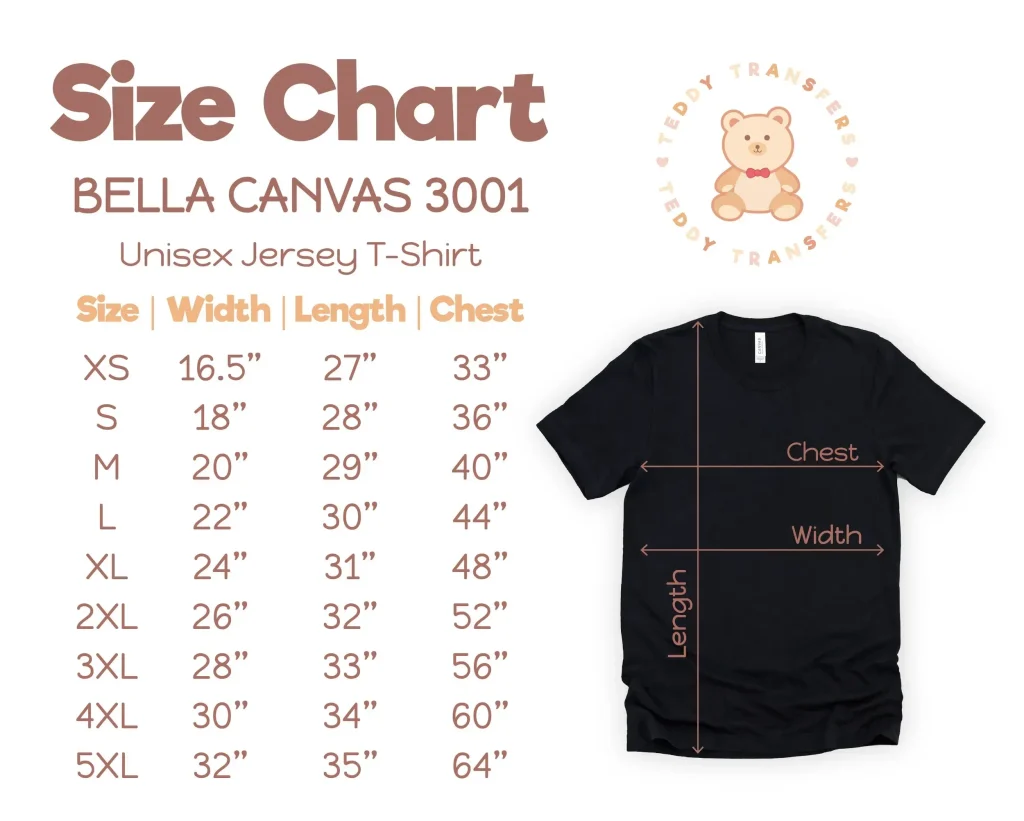

Moreover, determining optimal print sizes also requires a keen understanding of the specific garment’s dimensions. Every piece of apparel has designated printable areas, which limit how large a transfer can be. Familiarizing yourself with these areas will not only improve placement accuracy but also enhance the overall aesthetic of the printed garment. This attention to detail contributes significantly to customer satisfaction, as clients will receive high-quality products with prints that align perfectly with their expectations.

The Role of DTF Transfer Quality in Print Success

DTF transfer quality is largely influenced by the size of the transfer, as larger designs may require careful management to avoid mistakes. High-quality transfers are those that maintain vivid colors, sharp details, and an overall professional appearance. The quality standards of the print can vary dramatically with size; overly large prints may distort colors and reduce clarity, while well-sized transfers ensure that the design’s integrity is preserved. This highlights the necessity of balancing size with the inherent detailing of the artwork.

Additionally, achieving superior DTF transfer quality hinges on using the right inks and films as well. When the transfer size is accurately matched to the materials being used, it causes less stress on the design during application, leading to better adherence and a more durable outcome. Therefore, understanding how transfer size interacts with print quality is key to elevating your DTF printing process to produce outputs that stand the test of time.

Tips for Better DTF Printing with Size Consideration

To ensure excellence in DTF printing, there are several tips to optimize both size and quality. First, always utilize templates that accommodate various print sizes. This allows for easier scaling of designs without losing essential details. Furthermore, utilize design software that helps adjust sizes while maintaining resolutions to keep clarity intact. Planning your workflow to include size adjustments in the early stages can help streamline the entire printing process.

Another crucial tip is to familiarize yourself with the recommended heat press settings for different transfer sizes. Larger prints may require different heating and pressing considerations. Always conduct preliminary tests to fine-tune your machine for varying sizes, ensuring proper pressure and heat distribution. By following these tips, you will enhance your DTF printing capabilities significantly while minimizing common pitfalls associated with print sizes.

Material Selection for Varying DTF Transfer Sizes

Material selection plays a vital role in the compatibility of DTF transfers and their respective sizes. Different fabrics respond uniquely to transfer applications, especially when size variations are involved. For example, oversized prints may work wonderfully on robust cotton but might create complications when applied to delicate fabrics like silk. To avoid disappointing results, experiment with a variety of material blends to discover how they interact with various transfer sizes.

Moreover, it’s essential to consult manufacturer guidelines when selecting materials for DTF printing. Fabrics that are not suited for large prints may experience distortions that diminish the overall quality of the design. Conducting thorough tests with sample transfers on different materials will enhance your understanding of what works best, ensuring each DTF transfer not only looks good but lasts against wear and washing.

Emerging Techniques in DTF Printing and Transfer Size Adaptation

As DTF printing continues to evolve, new techniques are emerging that enhance the process of adjusting transfer sizes without compromising quality. Innovations in printing software now offer features that allow users to automatically scale designs based on the selected garment size while preserving the details vital to the design. By adopting these technologies in your printing workflow, you can save time and improve accuracy in size adjustments.

Furthermore, advancements in transfer materials and inks enable creators to push the boundaries of DTF printing. For instance, new film types can provide better adherence and clarity even at larger sizes, leading to more vibrant prints. Staying current with these emerging techniques will empower you to refine your printing processes, ensuring that you’re always delivering the highest quality and most visually appealing products to your customers.

Frequently Asked Questions

What is the ideal DTF transfer size for high-quality prints?

The ideal DTF transfer size varies depending on the design and the garment type. For optimal print quality, it’s essential to balance the size with the garment’s printable area to maintain detail and proper placement.

How does DTF transfer size affect the durability of prints?

DTF transfer size directly impacts durability; larger transfers may face adhesion issues, leading to peeling. It’s crucial to ensure the transfer size suits the garment fabric to enhance longevity and withstand washing.

What are the best DTF printing tips for managing transfer sizes?

To manage DTF transfer sizes effectively, always scale designs appropriately, conduct test prints, and adjust heat press settings specifically for larger prints. This ensures optimal adhesion and quality.

Can oversized DTF transfers lead to quality issues?

Yes, oversized DTF transfers can cause quality issues such as poor adhesion and loss of detail. Maintaining an optimal transfer size helps prevent these problems and ensures a high-quality finish.

What role does DTF transfer size play in design scaling?

DTF transfer size plays a crucial role in design scaling; improper sizing can lead to misplacement and loss of intricacies. Always adjust your designs to match the garment’s printable area for perfect results.

How can I ensure proper heat press settings for different DTF transfer sizes?

To ensure proper heat press settings for DTF transfer sizes, adjust pressure and temperature based on the size of the transfer. Conducting tests on sample prints helps optimize settings for the best adhesion.

| Key Point | Details |

|---|---|

| Understanding DTF Printing | DTF printing uses specialized inks and films to transfer vibrant designs onto fabrics, offering flexibility and intricate details. |

| Importance of DTF Transfer Size | DTF transfer size affects design scaling, print quality, adhesion, and material compatibility. |

| Design Scaling | Improper scaling can lead to loss of detail and misplacement on the item. |

| Impact on Print Quality | Larger prints may face adhesion issues and reduced durability. |

| Heat Press Settings | Larger transfers require adjusted pressure and heat settings for effective adherence. |

| Material Considerations | Fabric type and size compatibility are crucial for optimal results. |

| Recent Innovations | Advancements in software and techniques enhance the scaling and quality of DTF printing. |

Summary

DTF transfer size is a crucial aspect of producing high-quality prints in direct-to-film printing. An understanding of how transfer size impacts design scaling, print quality, heat press settings, and material compatibility is essential for achieving impeccable results. As the DTF printing technology continues to evolve, staying informed about these factors helps businesses enhance their product offerings and maintain a reputation for quality and reliability in printing services.