UV DTF transfers are setting a new standard in the printing world, merging cutting-edge UV printing technology with direct to film printing techniques. This innovative method stands out for its ability to produce stunningly vibrant, durable prints on a variety of surfaces, which is essential for businesses aiming to deliver high-quality products. As sustainable printing technology becomes increasingly essential, UV DTF transfers cater to this demand by minimizing environmental impact while maximizing print quality. The advancements in digital printing techniques associated with UV DTF make it a game-changer for anyone involved in custom printing. In this blog post, we will explore the science and technology behind UV DTF transfers, highlighting why they are the optimal choice for modern printing needs.

Often referred to as ultraviolet direct-to-film transfers, this printing method represents a remarkable evolution in print technology. By employing advanced curing processes, this form of DTF printing significantly enhances the vibrancy and longevity of prints, making it suitable for a vast array of materials beyond the limitations of traditional ink methods. The adoption of environmentally conscious printing practices is reinforced through these innovations, presenting businesses with a sustainable option that does not compromise on quality. As we delve deeper into this topic, we will uncover the myriad benefits and the latest developments in the landscape of UV DTF printing.

What Makes UV DTF Transfers Unique?

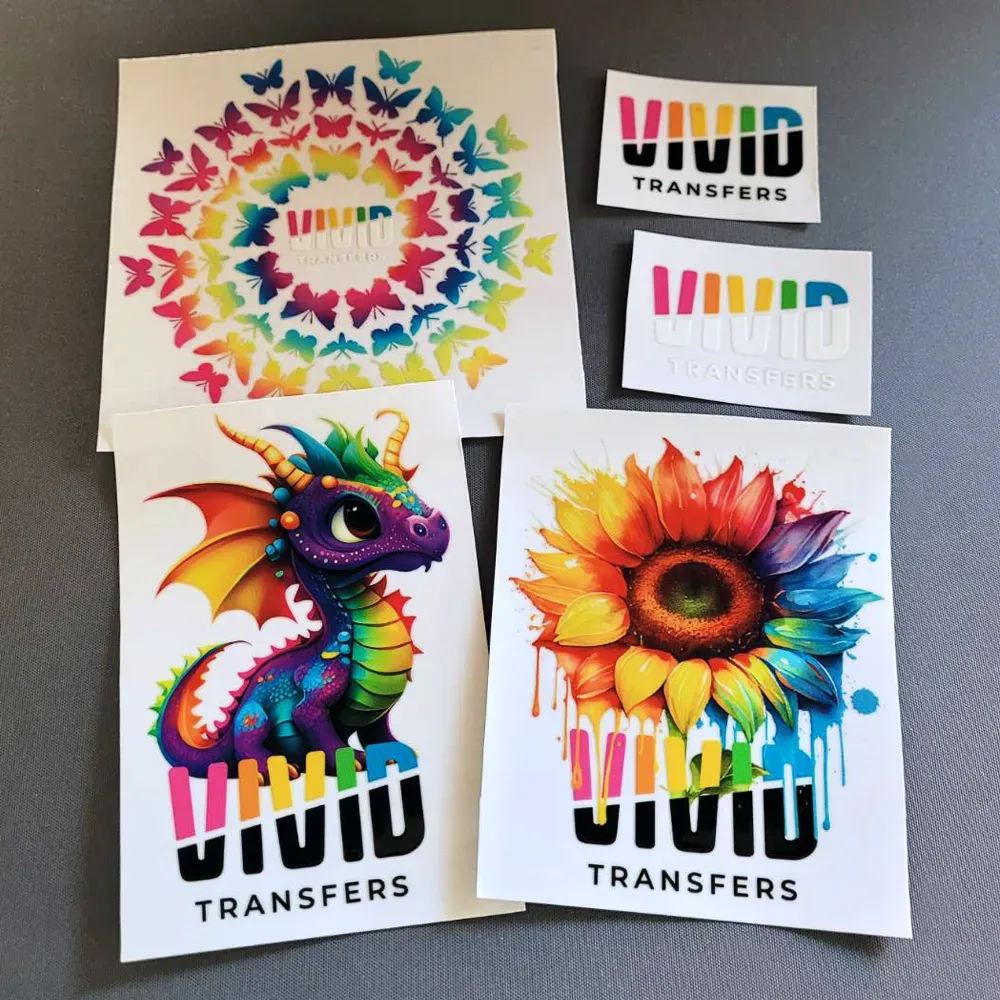

UV DTF transfers represent a bridge between traditional printing techniques and cutting-edge technology. This unique interplay allows businesses to produce high-quality prints with remarkable detail and color vibrancy. Unlike conventional methods, where the drying process can lead to delays and limited color choices, UV DTF uses ultraviolet light for instant curing, translating to faster production cycles and exceptional print quality. The versatility of UV DTF makes it suitable for various substrates, from textiles to rigid surfaces, enabling printers to cater to different market demands.

Furthermore, the UV curing process ensures that the prints maintain their integrity and durability over time. This is crucial for items that are subject to frequent handling or varying environmental conditions. The flexibility offered by UV DTF technology not only expands the types of products that can be printed but also sets a new standard in print quality advancements, making it a game-changer in the industry.

The Environmental Benefits of UV DTF Printing

With sustainability becoming increasingly important in the printing industry, UV DTF transfers stand out due to their eco-friendly attributes. Conventional solvent-based inks often release high levels of volatile organic compounds (VOCs), which can be harmful to both the environment and human health. In contrast, UV inks used in DTF transfers significantly reduce these emissions, aligning with global initiatives to promote cleaner production practices. This shift not only helps companies appeal to environmentally conscious consumers but also supports compliance with increasingly stringent environmental regulations.

In addition to low VOC emissions, UV DTF printing also utilizes less energy compared to some traditional processes, contributing to lower overall carbon footprints. As more companies adopt sustainable printing technologies, the focus on fine-tuning processes and materials will enhance the appeal of UV DTF printing, positioning it as a preferred solution for those prioritizing environmental responsibility in their business practices.

Advancements in UV DTF Technology

The landscape of UV DTF printing is rapidly evolving, with ongoing advancements in technology playing a pivotal role in its growth. Manufacturers are continually developing new machinery with improved features to meet the increasing demand for high-quality prints. These technological advancements include higher resolution printing capabilities, enhanced speed, and better compatibility with various substrates. The result is a more efficient production process that allows businesses to meet tight deadlines while maintaining exceptional print quality.

Moreover, recent enhancements in ink formulations have also improved the durability and flexibility of prints produced with UV DTF technology. This is particularly important for businesses that require prints to withstand daily wear and tear or exposure to outdoor elements. As equipment evolves, so does the potential for achieving even more striking color accuracy and detail, making UV DTF a forward-thinking solution for modern printing challenges.

Exploring Digital Printing Techniques with UV DTF

Digital printing techniques have transformed the way businesses think about customization and efficiency in their production lines, and UV DTF is leading the charge in this evolution. Printing directly onto film prior to transfer presents unique opportunities for creating detailed and personalized designs at scale. This method not only allows for high-quality imagery but also enhances the overall aesthetic appeal of the final product, which is crucial in competitive markets.

As digital printing continues to develop, the capabilities of UV DTF transfers will only expand. Tools and software have improved to integrate seamlessly into existing workflows, enabling creators to explore complex designs that were previously difficult to execute with traditional techniques. This synergy between digital advancements and UV technology facilitates creativity while ensuring that print quality remains consistently high across various job types.

Sustainable Printing Solutions with UV DTF

As consumer awareness grows regarding the environmental impact of their purchases, businesses are increasingly prioritizing sustainable printing solutions. UV DTF transfers offer an innovative way to fulfill this demand without sacrificing quality or performance. The technology’s ability to use eco-friendly inks while maintaining production efficiency positions it as a beneficial alternative to more traditional printing methods.

Companies adopting UV DTF technology not only demonstrate a commitment to sustainability but also attract customers seeking greener products. Additionally, aligning brand values with eco-friendly practices can enhance customer loyalty and strengthen market positioning. As industries continue to integrate sustainable initiatives, embracing UV DTF will help businesses remain relevant and responsive to evolving consumer preferences.

The Future of UV DTF Transfers in the Printing Industry

Looking ahead, UV DTF transfers are poised to redefine what is possible in the printing industry. The combination of instant curing technology and high-quality print outcomes offers a competitive edge that many businesses seek in today’s fast-paced market. As innovation in both equipment and materials continues, the potential applications for UV DTF technology will likely expand into new markets, pushing the boundaries of creative printing solutions.

Furthermore, as customer expectations shift towards quicker turnaround times and custom options, UV DTF provides a valuable solution that meets these demands. Continued investment in research and development within the field is expected to drive further improvements in speed, efficiency, and sustainability. Embracing these advancements will be crucial for businesses looking to stay ahead in an increasingly competitive environment.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers, or UV Direct to Film transfers, utilize ultraviolet technology to print vibrant images on a special film that is then transferred onto various substrates. This method employs UV light to instantly cure the ink, providing high-resolution prints that are durable and suitable for multiple surfaces such as textiles, wood, and metal.

What advantages do UV DTF transfers offer over traditional printing methods?

UV DTF transfers offer several advantages over traditional printing methods, including instant curing of ink which significantly reduces production times. They also provide high durability and vibrant colors, making them ideal for products that require frequent handling or outdoor exposure, along with the ability to print on a wide range of materials without the limitations of solvent inks.

How does UV DTF technology contribute to sustainable printing practices?

UV DTF technology contributes to sustainable printing practices by using UV inks that emit significantly lower levels of volatile organic compounds (VOCs) compared to traditional solvent inks. This eco-friendly approach not only meets the increasing consumer demand for sustainable products but also helps companies align with environmental goals in their production processes.

Can UV DTF transfers be used on diverse substrates?

Yes, UV DTF transfers are highly versatile and can be applied to a wide array of substrates, including fabrics, rigid materials like wood and metal, and even plastics. This adaptability makes UV DTF an excellent option for businesses seeking to offer a diverse range of customized products.

What recent advancements have been made in UV DTF printing technology?

Recent advancements in UV DTF printing include improved machinery that enhances the speed, quality, and efficiency of the printing process. Leading manufacturers are continually innovating their equipment to provide better print quality and durability, contributing to the growing popularity and demand for UV DTF transfers in the market.

Where can businesses find resources to learn more about UV DTF printing techniques?

Businesses can find valuable resources about UV DTF printing techniques on platforms such as Print Industry and Textile World. These resources offer insights into achieving optimal color matching, selecting substrates, and enhancing print quality, supporting businesses as they navigate the adoption of UV DTF technology.

| Key Point | Details |

|---|---|

| What is UV DTF Printing? | UV DTF printing involves printing ink onto a special film before transferring it to various substrates using UV light for instant curing. |

| Instant Curing | Employs UV light to cure ink immediately, speeding up production and enhancing efficiency. |

| Versatility | Can be used on various materials including fabrics, wood, and metal, offering broad application. |

| High Durability | Produces prints that withstand wear and tear due to the immediate curing process. |

| Eco-Friendly Aspects | Has lower VOC emissions compared to traditional inks, aligning with sustainability trends. |

| Market Growth and Demand | The UV printing market is expected to expand due to increasing demand for custom products. |

| Recent Advancements | Leading manufacturers are enhancing equipment for better speed and quality in UV DTF printing. |

| Educational Resources | Platforms provide knowledge on optimal techniques, substrates, and color matching as technology evolves. |

Summary

UV DTF transfers signify a groundbreaking development in the printing industry, blending advanced UV technology with traditional DTF techniques to deliver top-tier print quality and efficiency. This method not only provides vibrant and sharp details, but also allows for quick curing of inks on diverse surfaces, enhancing production times and operational versatility. Furthermore, the environmental benefit of lower VOC emissions positions UV DTF printing as a sustainable choice, catering to a growing demand for eco-friendly solutions. With continued innovations and rising market demands, UV DTF transfers are set to become integral in custom printing, making them a compelling option for businesses aiming to leverage the latest technological advancements.