In the rapidly evolving world of printing, **UV DTF Transfers** have emerged as a game-changer, surpassing many **traditional printing methods** in quality and versatility. This innovative technique utilizes ultraviolet light to cure inks, resulting in vibrant and enduring prints that meet the growing demands of customization and efficiency. Unlike **screen printing** and other established methods, UV DTF offers significant advantages such as quicker production times and the ability to print on a wide range of surfaces without compromising durability. As businesses explore options for **custom printing**, understanding the cost-effectiveness of this method becomes crucial. Join us as we delve deeper into the benefits and comparisons of UV DTF Transfers against traditional printing methods, ensuring you are well-equipped to choose the best option for your unique project needs.

Often referred to simply as DTF, **UV DTF Transfers** represent a groundbreaking approach that utilizes specialized UV technology to produce high-quality prints. This method stands out among conventional processes like **screen printing** and **offset printing**, primarily due to its ability to deliver brilliant colors and exceptional durability without the need for heat. In today’s market, businesses are increasingly looking for more efficient and dynamic printing solutions, and DTF printing fulfills this demand with its adaptability to various materials. The discussion around **screen printing vs DTF** revolves not only around the fundamental differences in method but also highlights the cost-effectiveness and superior quality offered by UV DTF Transfers. As we explore the ins and outs of these printing techniques, you’ll discover how they cater to modern printing needs while ensuring durable and eye-catching results.

Understanding UV DTF Transfers

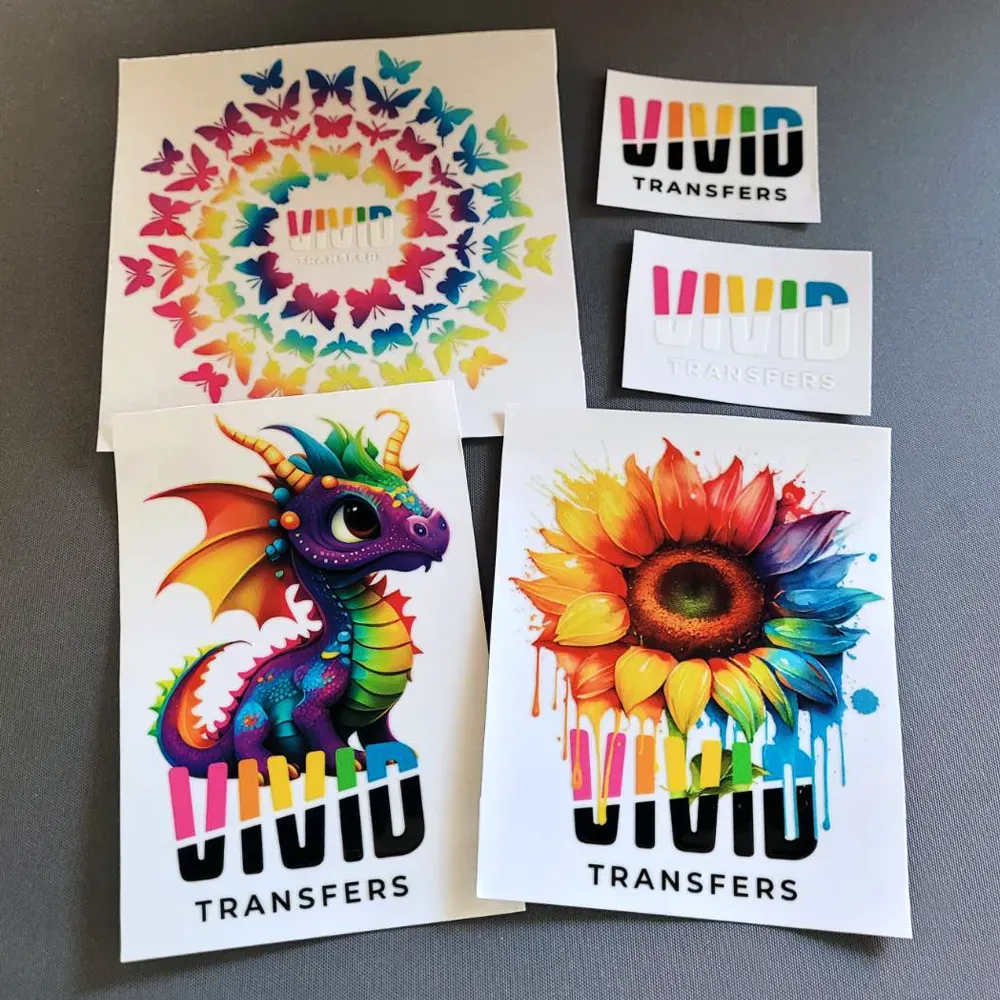

UV DTF Transfers, or Direct to Film transfers, are revolutionizing the printing industry with their innovative approach to applying ink. Utilizing ultraviolet light to cure inks, this method creates designs that are not only visually stunning but also incredibly durable. Unlike traditional methods that may involve heating and extensive setup, UV DTF printing streamlines the process, allowing for efficient customization of projects. This feature is particularly desirable for businesses looking to produce unique items without the need for large quantities, making it a perfect fit for promotional materials, custom clothing, and more.

The impact of UV DTF Transfers extends beyond just aesthetic appeal. With their high resistance to scratches and fading, these prints are suitable for various items, including both fabric and rigid surfaces. This versatility showcases the capability of UV DTF not only to adapt to different materials but also to maintain high quality across diverse applications. Moreover, the technology supports shorter production times, enabling businesses to meet tight deadlines while still delivering exceptional products.

Durability of UV DTF vs Traditional Printing Methods

One of the significant advantages of UV DTF Transfers lies in their exceptional durability compared to traditional printing methods. Conventional techniques like screen printing often face challenges concerning the longevity of their prints, especially when exposed to varying environmental conditions. In contrast, UV DTF prints exhibit remarkable resistance to wear and tear, ensuring that colors remain vibrant and details intact over extended periods. This durability is crucial for products that will undergo rigorous handling or outdoor exposure, providing businesses with reliable solutions that enhance their product offerings.

Furthermore, durability in printing can significantly influence customer satisfaction and brand reputation. Companies that prioritize quality and longevity in their products often find that UV DTF provides a competitive edge in the market. Customers are more likely to return for additional purchases when they know that a brand offers long-lasting quality. Thus, when considering the durability aspect, UV DTF Transfers emerge as a superior choice for businesses aiming to uphold a high standard of product excellence.

Cost-Effectiveness of UV DTF Printing

When evaluating cost-effectiveness in printing, several factors come into play, particularly concerning the scale of production. UV DTF Transfers provide significant advantages for smaller, customized runs, where traditional methods like screen printing may not prove as economical. The initial setup costs for screen printing, while offset by lower per-unit costs in bulk, can deter businesses from producing limited-edition or unique items. Conversely, UV DTF allows for lower entry costs, enabling businesses to create smaller batches without incurring excessive expenses.

Additionally, the quick turnaround associated with UV DTF printing can translate to reduced labor and time costs, particularly critical for companies that cater to fast-paced markets. When companies reevaluate their printing strategies, they often find that UV DTF not only meets their quality demands but also contributes to better financial management in the long run. This cost-effectiveness ultimately empowers businesses to remain agile and responsive to market trends without sacrificing quality.

Customization Capabilities of UV DTF Printing

Customization represents a significant trend in the modern printing landscape, and UV DTF Transfers excel in this area. The technology allows for intricate designs and a wide spectrum of color choices, accommodating the specific needs of diverse clients. Unlike traditional printing methods, which may impose limitations on design complexity and color variations, UV DTF fosters creativity by making it easier to experiment with different styles and materials. This flexibility appeals to businesses eager to differentiate themselves in a saturated market.

Furthermore, UV DTF enables a faster design-to-production cycle, allowing brands to respond to consumer demands swiftly. As trends evolve and the need for personalization grows, the ability to produce custom designs rapidly becomes a valuable asset. By leveraging the strengths of UV DTF, businesses can offer tailored products that resonate with their customer base, ultimately enhancing their market positioning.

The Environmental Impact of UV DTF Transfers

As sustainability becomes an increasingly important consideration, the environmental impact of printing methods cannot be overlooked. UV DTF Transfers are often regarded as a more environmentally friendly option compared to traditional printing methods. The use of UV light to cure inks minimizes the need for harmful chemicals, which are typically prevalent in screen printing and offset printing. This aspect of UV DTF not only aligns with eco-conscious consumer preferences but also supports businesses in adopting greener practices.

In addition to reduced chemical usage, UV DTF printing often results in lower energy consumption during production. This efficiency creates a compelling case for companies that are aiming to lessen their carbon footprint while still producing high-quality prints. As brands increasingly commit to sustainability, choosing methodologies like UV DTF can serve as a strong message to consumers about their environmental responsibility, reinforcing positive brand image and customer loyalty.

Comparative Analysis: Screen Printing vs. UV DTF Transfers

In the printing industry, screen printing has long been a go-to method for producing bold designs on a large scale. While it excels in cost-effectiveness for bulk orders, it does come with certain limitations that UV DTF Transfers adeptly overcome. For instance, screen printing can struggle with intricate imagery or color gradients, often requiring multiple screens and setups that may slow down the production process. In contrast, the UV DTF technology not only simplifies printing fine details but also allows for unlimited colors in a single pass, making it a more versatile option for artists and designers.

Moreover, when considering overall production time and flexibility, UV DTF Transfers shine brightly. The ability to quickly switch between projects or adapt designs at a moment’s notice removes barriers that traditional screen printing might present. For businesses that prioritize swift adaptation and high-quality output across a range of fabrics and materials, making the switch from screen printing to UV DTF can result in remarkable benefits in workflow efficiency and product diversity.

Frequently Asked Questions

What are the main advantages of UV DTF Transfers compared to traditional printing methods?

UV DTF Transfers provide several advantages over traditional printing methods, including vibrant colors that remain rich and deep, enhanced durability against scratches and fading, and versatility in application across various materials. This method also eliminates the need for heat in the printing process, allowing for quicker turnarounds and customization options, making it ideal for smaller projects or unique designs.

How does the durability of UV DTF Transfers stack up against screen printing?

The durability of UV DTF Transfers generally surpasses that of screen printing. UV DTF prints are highly resistant to wear and tear, ensuring they maintain their quality and vibrancy over time without significant degradation. In contrast, screen printing may experience fading or wear, especially for intricate designs or items subjected to heavy use.

Are UV DTF Transfers more cost-effective than traditional printing methods for small runs?

Yes, UV DTF Transfers are often more cost-effective for small print runs as they do not require extensive setups compared to traditional methods like screen printing. While traditional printing can be more economical for large quantities due to lower per-unit costs after setup, UV DTF offers a competitive alternative for businesses needing customized or smaller quantities without the additional costs.

What types of surfaces can UV DTF Transfers be applied to, compared to traditional printing techniques?

UV DTF Transfers can be applied to a wide range of surfaces, including various textiles, hard materials like wood and glass, and even plastic. In comparison, traditional printing techniques like screen printing may have limitations based on the materials used, potentially leading to increased waste or challenges in achieving desired effects on certain substrates.

How does the environmental impact of UV DTF Transfers compare with traditional printing methods?

UV DTF Transfers are generally considered more environmentally friendly than traditional printing methods. The UV curing process often utilizes fewer harmful chemicals and consumes less energy during production. In contrast, many traditional methods still rely on solvents and inks that may have a more significant environmental impact.

Which printing method is better for high customization projects: UV DTF Transfers or traditional printing?

For high customization projects, UV DTF Transfers are typically the better choice. This method accommodates unique designs, quick turnaround times, and various material applications without the stringent setup requirements of traditional printing methods. As a result, businesses can easily adapt their designs and meet specific client needs efficiently.

| Key Points | UV DTF Transfers | Traditional Printing Techniques |

|---|---|---|

| Definition | Utilizes ultraviolet light to cure inks for vivid designs | Includes screen printing, offset printing, and digital printing |

| Advantages | 1. Vibrant colors 2. High durability 3. Versatile applications | 1. Cost-effective for large runs 2. Established techniques 3. Consistency in quality |

| Technology and Process | Uses advanced technology without heating, allowing for quicker setups | Generally requires heating; slower production setup |

| Durability and Quality | Resistant to wear and tear with long-lasting quality | Quality degradation may occur over time, especially with intricate designs |

| Application Versatility | Compatible with various surfaces and designs; ideal for smaller jobs | Limited to traditional materials; might lead to waste with unique jobs |

| Cost and Production | More advantageous for smaller, customized jobs | Lower per-unit cost for large volume productions |

| Environmental Impact | More eco-friendly with reduced chemicals and energy use | Can involve harmful solvents and inks |

Summary

UV DTF Transfers are revolutionizing the printing landscape by offering an innovative approach that combines vibrant color application, durability, and versatility across various materials. Unlike traditional printing methods, UV DTF leverages advanced technology using ultraviolet light for curing inks, which not only enhances the visual output but also significantly improves the longevity and scratch resistance of printed designs. This method stands out especially for businesses seeking quick turnaround times and customization options for smaller batches. On the other hand, traditional printing methods like screen and offset printing still prove to be beneficial for large-scale productions due to their cost-effectiveness and reliability. However, as environmental concerns take precedence, UV DTF’s reduced chemical usage offers a more sustainable choice for modern printing needs. Therefore, businesses should carefully assess their project specifics when choosing between UV DTF Transfers and traditional methods to ensure optimal results.