In the vibrant world of custom printing, UV DTF transfers have rapidly gained popularity as an innovative technique for creating eye-catching designs. Whether you’re a seasoned professional or a passionate DIYer, mastering how to apply UV DTF transfers can elevate your projects to a whole new level. This process involves printing intricate designs onto a unique transfer film that is then cured with UV light, resulting in stunning and durable prints. With the right knowledge and best practices for UV DTF transfers, you can achieve vibrant colors that truly stand out on various substrates. Join us as we delve into the essential steps and techniques needed for a successful DIY UV DTF application, and unlock the full potential of this exciting printing method.

UV DTF transfers, also known as Direct to Film UV printing, represent a groundbreaking approach to design transfer, allowing both professionals and hobbyists to showcase their creativity. This method combines advanced UV ink technology with transfer film to produce high-quality images that adhere seamlessly to a multitude of surfaces. By understanding the UV ink curing process, users can ensure that their prints are not only vivid but also long-lasting and resistant to wear. As we explore this topic, we will uncover alternative methods, tips, and tricks that contribute to a successful application, making the most of this versatile printing technique.

Introduction to UV DTF Transfers

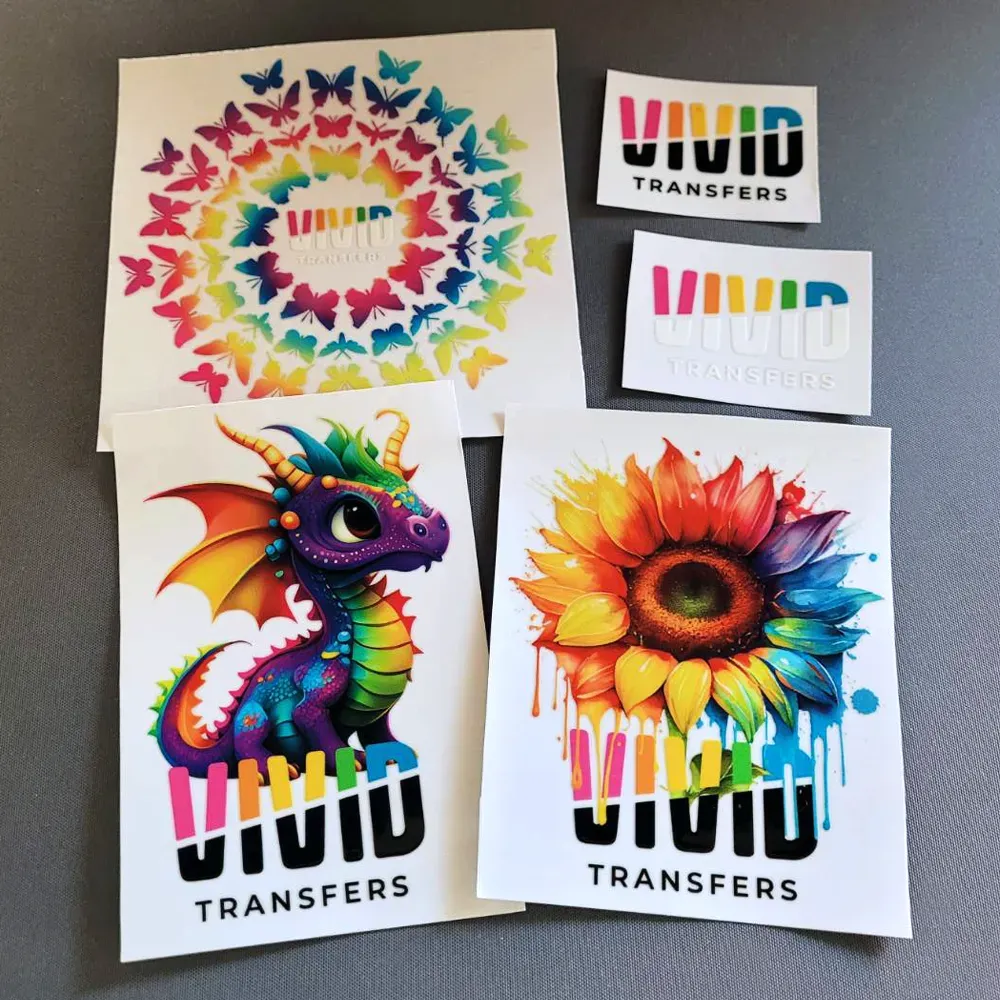

UV DTF (Direct to Film) transfers have rapidly gained popularity among DIY enthusiasts and professionals alike due to their versatility and ease of use. This innovative printing technology allows users to create vibrant and intricate designs that can be applied to various substrates, from textiles to ceramics. The process involves transferring specially printed designs onto a film, followed by curing the inks with UV light, creating a durable finish that stands the test of time.

The appeal of UV DTF transfers lies in their potential for high-quality results that rival traditional printing methods. Unlike conventional transfer methods, which may fade or wear off quickly, UV prints are known for their resilience and vivid colors. This subheading introduces you to the fundamental aspects of UV DTF transfers and sets the stage for a deeper dive into the application techniques that can elevate your DIY projects.

Materials Required for Effective UV DTF Transfers

To successfully apply UV DTF transfers, the right materials are essential. First and foremost, you’ll need a dedicated UV DTF printer capable of handling UV inks, which produce bright and detailed prints on transfer film. Alongside the printer, acquiring high-quality transfer film will ensure optimal ink transfer and adhesion to your chosen substrate. Additionally, investing in a reliable UV curing lamp is crucial, as it facilitates the curing process, solidifying the inks and enhancing their durability.

Don’t forget the importance of a heat press or a hand applicator, especially for intricate designs or when working with uneven surfaces. The substrate itself also plays a vital role; selecting compatible materials such as cotton, polyester, or hard surfaces can significantly influence the transfer’s success. Preparing these materials thoroughly will lay the foundation for a smooth application process and a long-lasting finished product.

Step-by-Step Guide to Applying UV DTF Transfers

The application of UV DTF transfers can be broken down into a few simple yet critical steps that help achieve professional results. Start by printing your chosen design on the transfer film using your UV DTF printer. Be mindful to select the appropriate printer settings, adjusting factors like ink density and resolution to ensure a sharp and vibrant end result. Once printed, take the time to prepare the substrate by cleaning its surface to avoid any interference with the transfer.

When you correctly place the transfer film onto the substrate, it’s essential to apply even pressure. Depending on the material, a heat press may provide uniformity that hand application cannot. Following the transfer application, curing the ink with the UV lamp is the final and most crucial step in ensuring durability. This process solidifies the design, making it resistant to wear and ensuring bright colors remain intact.

Best Practices for Successful UV DTF Application

To achieve the best results when applying UV DTF transfers, understanding best practices is key. One of the most important tips is to experiment with different substrates; not every transfer will adhere well to every material. By testing various surfaces, you can find the perfect match that ensures optimal adhesion and durability. Additionally, it’s wise to adjust your printer settings according to the type of transfer film being used, as different brands may require tailored configurations.

Another best practice involves proper curing of the inks. Ensuring your UV curing lamp is at the correct distance from the design and calibrating the exposure time is critical. Over-curing can lead to brittle prints that may peel off, while under-curing can result in fading or smudging. Mastering these elements will significantly enhance your UV DTF results, elevating your projects from amateur to professional quality.

Understanding the UV Ink Curing Process

The UV ink curing process is a pivotal aspect of applying UV DTF transfers, determining the longevity and vibrancy of your printed designs. Curable inks utilize UV light to initiate a chemical reaction called polymerization, which transforms liquid inks into solid forms upon exposure. Understanding this process is fundamental to securing a high-quality transfer, as the curing stage ensures that inks adhere properly and resist common issues like fading or washing out.

When using a UV lamp, it’s essential to follow the manufacturer’s recommendations for distance and exposure settings to achieve optimal results. Proper calibration will prevent problems such as insufficient curing, which can lead to transfers that crack or peel away. By mastering the UV ink curing process, you can ensure that your projects not only look stunning but also withstand the test of time, providing long-lasting satisfaction.

Resources for Mastering UV DTF Transfers

As you embark on your journey with UV DTF transfers, accessing reliable resources can provide you with the knowledge and confidence to refine your skills. Online platforms like YouTube serve as valuable teachers, featuring countless video tutorials that break down the application process and troubleshooting tips, making learning accessible and engaging. These visual aids can be particularly helpful for beginners who appreciate a step-by-step guide to mastering complex techniques.

Additionally, online communities and forums such as Signs101 and Print Industry offer a wealth of information, providing insight through shared experiences of both hobbyists and professionals. Interacting with these communities gives you access to expert advice, from solving specific issues to exploring advanced techniques in UV DTF printing. With these resources at your disposal, you’ll be well-equipped to take your projects to the next level.

Frequently Asked Questions

What are the best practices for UV DTF transfers?

To ensure successful UV DTF transfers, follow these best practices: always use a high-quality UV DTF printer and transfer film, properly prepare the substrate by cleaning it thoroughly, and optimize your printer settings for the specific film you are using. Additionally, ensure that your UV lamp is calibrated correctly for the distance and exposure time during the curing process.

How do you apply UV DTF transfers effectively?

Applying UV DTF transfers involves several steps: first, print your design onto the transfer film using a UV DTF printer. Next, prepare the substrate by cleaning it. Then, place the film onto the substrate, often using a heat press, and finally cure the ink with a UV lamp to ensure adherence and durability. Testing on various substrates will help optimize your technique.

What materials are needed for DIY UV DTF application?

For DIY UV DTF application, you’ll need a UV DTF printer, transfer film, a UV curing lamp, and a heat press or hand applicator depending on your substrate. Additionally, ensure you have a clean substrate ready for applying your design, whether that’s textiles, ceramics, or hard surfaces.

How does the UV ink curing process work in UV DTF transfers?

The UV ink curing process in UV DTF transfers works by exposing the printed ink on the transfer film to UV light, which initiates a chemical reaction that hardens the ink. This curing creates a durable bond between the ink and the substrate, resulting in vibrant and long-lasting designs.

Can I use UV DTF transfers on any substrate?

While UV DTF transfers can be applied to a variety of substrates, including textiles and ceramics, the adhesion can vary. It’s important to test various materials to determine which ones work best with your specific UV DTF process, as certain surfaces may require different preparation or curing techniques.

What troubleshooting tips can help with UV DTF transfers?

Common troubleshooting tips for UV DTF transfers include adjusting your printer settings for optimal ink density, ensuring your substrate is completely clean for better adhesion, and calibrating the distance and exposure time of your UV lamp to prevent issues like ink peeling or fading. If problems persist, monitoring the curing process closely can help identify the source of any inconsistencies.

| Key Point | Description |

|---|---|

| Introduction | Overview of UV DTF transfers and their significance in custom printing. |

| What are UV DTF Transfers? | A printing method that utilizes transfer film and UV light to create vibrant, durable prints. |

| Materials Needed | Essential items such as UV DTF printer, transfer film, curing lamp, heat press, and substrates. |

| Step-by-Step Application Process | Detailed process covering printing, preparing substrates, applying transfers, curing ink, and finishing. |

| Tips for Success | Advice on testing substrates, adjusting printer settings, and ensuring curing lamp calibration. |

| Resources for Further Learning | Tutorials and guides available on platforms like YouTube and community blogs. |

Summary

UV DTF transfers are a revolutionary technique in the world of custom printing, allowing anyone to apply designs with professional flair. By using specialized materials and following a meticulous application process, you can create exquisite prints on a variety of surfaces. This method has made it easier for DIY enthusiasts to realize their creative visions, transforming simple projects into striking visual statements. With practice and the right techniques, you too can master the art of UV DTF transfers and produce stunning results.