DTF transfer by size is reshaping the custom printing landscape, empowering businesses to offer tailored solutions to their clientele. This innovative DTF printing technology not only meets diverse garment printing needs but also ensures that every design is executed with remarkable precision. As the demand for personalized apparel skyrockets, understanding the nuances of size-specific DTF transfers becomes essential for any brand looking to stay competitive. By leveraging this method, businesses can achieve cost-effective printing solutions while also committing to sustainable practices. Join us as we explore how DTF transfers by size can elevate your offerings and satisfy the evolving tastes of consumers.

Exploring DTF transfer by size unlocks a world of possibilities in garment customization, where the ability to print diverse sizes enhances the creative potential for businesses. Known as Direct-to-Film technology, this method revolutionizes how custom prints are approached, providing the flexibility to accommodate everything from intricate, small designs to bold, expansive graphics. With growing attention on cost-effective printing methods, integrating size adaptability into your offerings can significantly attract a wider audience. Furthermore, the emphasis on sustainable printing practices within this technology appeals to eco-conscious consumers seeking responsibly-made products. Dive deeper into the advantages of variable size DTF transfers and transform your printing strategy today.

Understanding the Basics of DTF Printing

DTF printing, or Direct-to-Film printing, is a modern technique revolutionizing the custom printing industry. This process involves printing images onto a special film that can then be transferred directly onto garments using heat and pressure. DTF is particularly valued for its versatility, enabling prints on various fabric types—including cotton, polyester, and blends—allowing businesses to cater to a wide audience. This adaptability means that whether you’re targeting sports teams, fashion lines, or promotional materials, DTF printing can provide solutions that fit every need.

From vibrant colors to intricate designs, DTF printing maintains high-quality output across different sizes. This capability is crucial as companies shift towards offering customizable products that resonate well with consumers. Unlike traditional printing methods, DTF allows for easy application of designs without the need for extensive setup, making it an attractive option for both small-scale operations and large print shops.

DTF Transfer by Size: Why It’s Important

Understanding **DTF transfer by size** is essential for any printing business aiming to meet varying consumer demands. The size of the transfer can significantly influence not just the aesthetic of the final product but also its marketability. With the rise in personalized garment requests, businesses must be able to offer sizes that cater to everything from intricate logos on small items like hats to bold graphics on large apparel like jackets.

Another area where size impacts DTF transfers is in production efficiency. Correctly sizing transfers can reduce waste during printing and ensure that materials are utilized effectively. By implementing a systematic approach to measuring transfer sizes, businesses can optimize their workflow and lower costs, which is crucial in a competitive market where pricing can determine customer loyalty.

Maximizing Print Quality Across Various Sizes

One of the standout advantages of DTF printing is the exceptional quality it delivers, regardless of the print size. The technology used in DTF printing has advanced significantly, allowing for crisp and vibrant reproductions that maintain their integrity whether printed on small tags or large fabric swathes. This high-quality print resolution is vital for customer satisfaction and can differentiate a brand in a crowded marketplace.

Furthermore, maintaining print quality over different sizes ensures that businesses can meet the rising expectations of consumers. Today’s customers look for detailed, aesthetically pleasing designs, and DTF technology allows for intricate detailing that other printing methods may struggle to achieve. Adapting print strategies to ensure optimal quality across all sizes not only drives sales but builds a reputation for reliability and excellence.

Harnessing Cost-Effectiveness with DTF Transfers

Cost efficiency in printing is often a key concern for businesses looking to expand their product range. One of the compelling benefits of **DTF transfer by size** is its ability to reduce costs, especially when dealing with bulk orders. Unlike traditional printing methods, which might incur higher costs for larger designs, DTF printing allows for economies of scale where costs per unit decrease as order sizes increase.

This aspect makes DTF printing particularly appealing to small businesses that want to produce high-quality products but have limited budgets. By optimizing transfer sizes and using strategic production practices, companies can deliver affordable custom prints without sacrificing quality or customer satisfaction, creating a win-win scenario for both business owners and consumers.

Sustainability in DTF Printing Practices

As the global community increasingly emphasizes sustainability, businesses must adapt their practices accordingly. DTF printing techniques can align well with eco-friendly initiatives by using sustainable inks and materials. Many DTF manufacturers are now offering products that adhere to green standards, including recyclable films and low-impact inks. This shift towards sustainability can help attract today’s environmentally-conscious consumers who prioritize businesses with ethical practices.

Incorporating **sustainable printing** into your DTF operations not only responds to market demand but can also position your brand as a leader in social responsibility. By promoting eco-friendly options, you demonstrate commitment to reducing environmental impacts while still delivering high-quality, vibrant prints that appeal to a broader audience.

Innovating with DTF Transfer Sizes

Innovation is at the heart of staying relevant in the printing industry. By experimenting with **DTF transfer by size**, businesses can explore new design possibilities that challenge traditional norms. For instance, offering oversized graphics or tailored smaller designs can create unique products that stand out. This experimentation leads to cutting-edge offerings that can attract adventurous customers looking for something special in their apparel.

Moreover, this spirit of innovation fosters creativity among designers and print operators, allowing them to push the boundaries of what can be achieved with DTF printing. By embracing challenges and thinking outside the box, businesses can capitalize on emerging trends and take advantage of niche markets within the custom printing landscape.

Frequently Asked Questions

What is DTF transfer by size and how does it work in custom printing?

DTF transfer by size refers to the adaptability of Direct-to-Film (DTF) printing technology in producing custom prints across a variety of garment sizes. This process involves printing designs on a special film, which is then transferred onto a fabric using heat and pressure. Its versatility allows businesses to cater to specific customer demands for both small and large designs, enhancing their custom printing capabilities.

How does DTF printing technology improve print quality for different sizes?

DTF printing technology is renowned for producing high-resolution and vibrant graphics, regardless of size. Innovations in DTF printers ensure that intricate designs maintain clarity when printed across various dimensions. This capability is crucial for businesses that prioritize quality in their products, as it meets the increasing consumer expectation for detailed custom prints on apparel.

Can DTF transfer by size offer cost efficiencies for bulk printing?

Yes, DTF transfer by size can provide significant cost efficiencies, especially for bulk orders. While larger designs may typically raise costs in other printing methods, DTF printing can lower the cost per unit due to its streamlined process, making it an economical solution for both small businesses and large-scale production.

What are the environmental benefits of using DTF printing for custom garments?

DTF printing supports sustainable printing practices as many manufacturers use eco-friendly films and inks. By focusing on DTF transfer by size, businesses can minimize waste and deliver high-quality designs without compromising environmental values, appealing to consumers who prioritize sustainability.

How can I determine the appropriate size for DTF transfers on different garments?

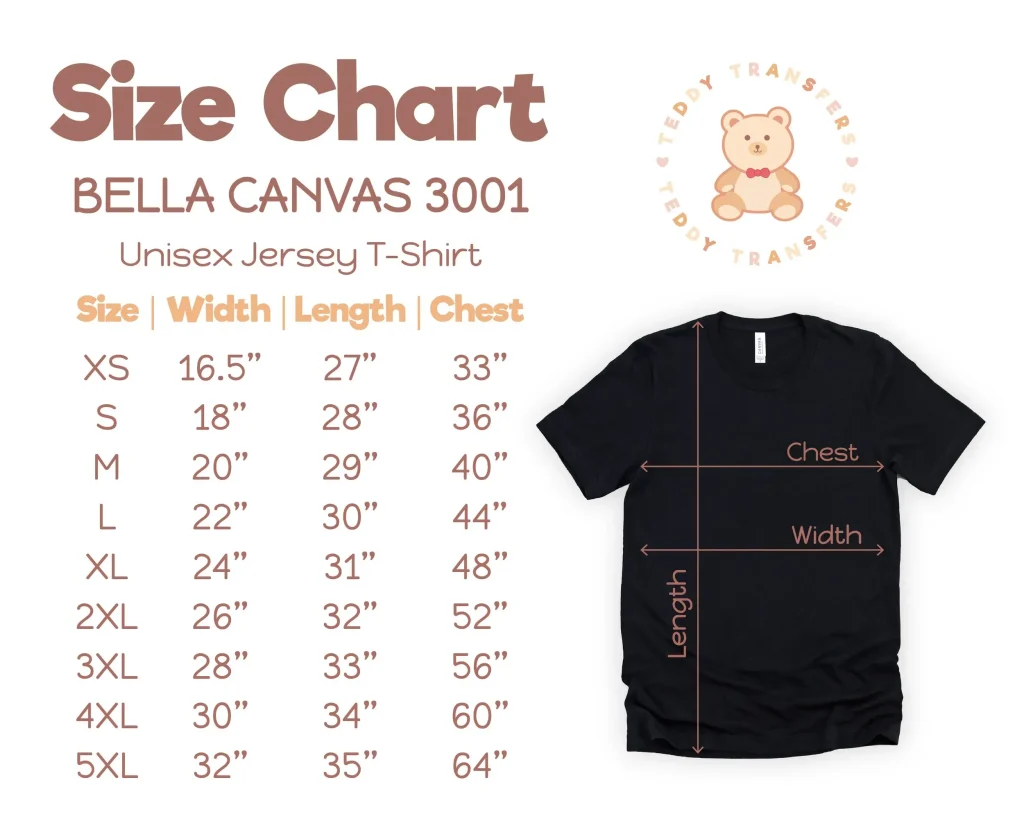

To determine the right size for DTF transfers, businesses should create templates that reflect the dimensions of various garment types. By understanding the specific requirements for items such as t-shirts, hoodies, or caps, you can customize transfer sizes to ensure the design fits well, enhancing the overall appearance of the custom print.

What should I consider when investing in DTF printing technology for size versatility?

When investing in DTF printing technology, consider the printer’s ability to handle a variety of sizes without sacrificing print quality. Look for equipment that offers flexibility, high resolution, and compatibility with diverse fabrics to ensure that you can effectively adopt DTF transfer by size in your custom printing operations.

| Key Point | Description |

|---|---|

| Introduction to DTF Transfers | A process where designs are printed on a special film, which is then transferred to fabric using heat and pressure. |

| Why Size Matters | |

| 1. Addressing Market Demand | DTF technology allows businesses to fulfill the demand for personalized garment options, accommodating both small and large orders. |

| 2. Enhanced Print Quality and Resolution | DTF printers produce intricate, high-quality designs with clarity across varying sizes. |

| 3. Cost Efficiency in Bulk Printing | Larger designs can reduce the cost per unit for bulk orders, making quality more affordable. |

| 4. Sustainability Matters | Eco-friendly films and inks in DTF printing meet sustainability demands while delivering beautiful prints. |

| Applying DTF Transfer by Size | |

| 1. Invest in Quality DTF Equipment | Ensure the latest printers handle a range of sizes with high resolution. |

| 2. Customize Transfer Sizes for Different Garments | Create templates and adjust sizes for varying garment types. |

| 3. Experiment with Designs and Sizes | Testing different combinations can lead to unique, attractive products. |

| 4. Promote Eco-Friendly Practices | Use sustainable aspects as a selling point to attract consumers. |

Summary

DTF Transfer by Size plays a pivotal role in enhancing custom print capabilities, allowing businesses to cater to diverse consumer needs effectively. By leveraging state-of-the-art DTF technology, companies can produce high-quality prints that accommodate both small and large designs while promoting cost efficiency and sustainability. As the market evolves, embracing the versatility of DTF transfers not only meets current demands but also opens up new opportunities for creative expression in garment printing. Recognizing the significance of size in DTF transfers can thus be a strategic advantage in today’s competitive printing landscape.