DTF transfer by size is a precision game that goes beyond simple scaling, shaping how clean edges and accurate placements look on garments. As you resize designs for shirts, bags, or hoodies, DTF sizing decisions become a practical factor for alignment and overall impact. Mastery here means balancing image quality, fabric behavior, and your prepress workflow to keep edges sharp and DTF print quality high. Using clear guidelines like the DTF alignment guide and these DTF transfer tips helps ensure predictable results across runs. From small logos to large back prints, focusing on sizing can improve DTF longevity on fabrics while supporting dependable results.

In other terms, scalable artwork for garments—often described as proportional resizing or size-aware printing—focuses on consistent placement across seams and curved panels. Think in terms of alignment fidelity, vector versus raster scaling, and maintaining edge integrity as the fabric stretches. This approach aligns with the broader concept of direct-to-film transfer optimization, ensuring color fidelity and readability across multiple garment types. By using alternative terms like layout adaptation, proportionate artwork, and panel-based sizing, you tap into related topics such as guidance for placement, print quality, and durability. Ultimately, adopting these LSI-driven concepts helps designers and printers achieve consistent, durable results across lines and seasons.

DTF transfer by size: mastering alignment, scaling, and longevity

DTF transfer by size isn’t just resizing a design; it’s about maintaining alignment as you scale for different garments and placements. By applying the DTF alignment guide during the sizing process, you can preserve centerpoints, edge distances, and balance across seams, collars, or sleeves. When you resize, keep the aspect ratio intact to avoid distortion, and verify the grid alignment after any scale change to ensure consistent results across items.

Beyond placement, the longevity of a size-adjusted transfer depends on proper curing, prepress prep, and testing. Use test prints to confirm that color density, edge sharpness, and overall print quality hold up when the design is enlarged or reduced. This disciplined approach helps ensure DTF longevity on fabrics and consistent performance in real-world wear and washing.

DTF sizing strategies for different garment types

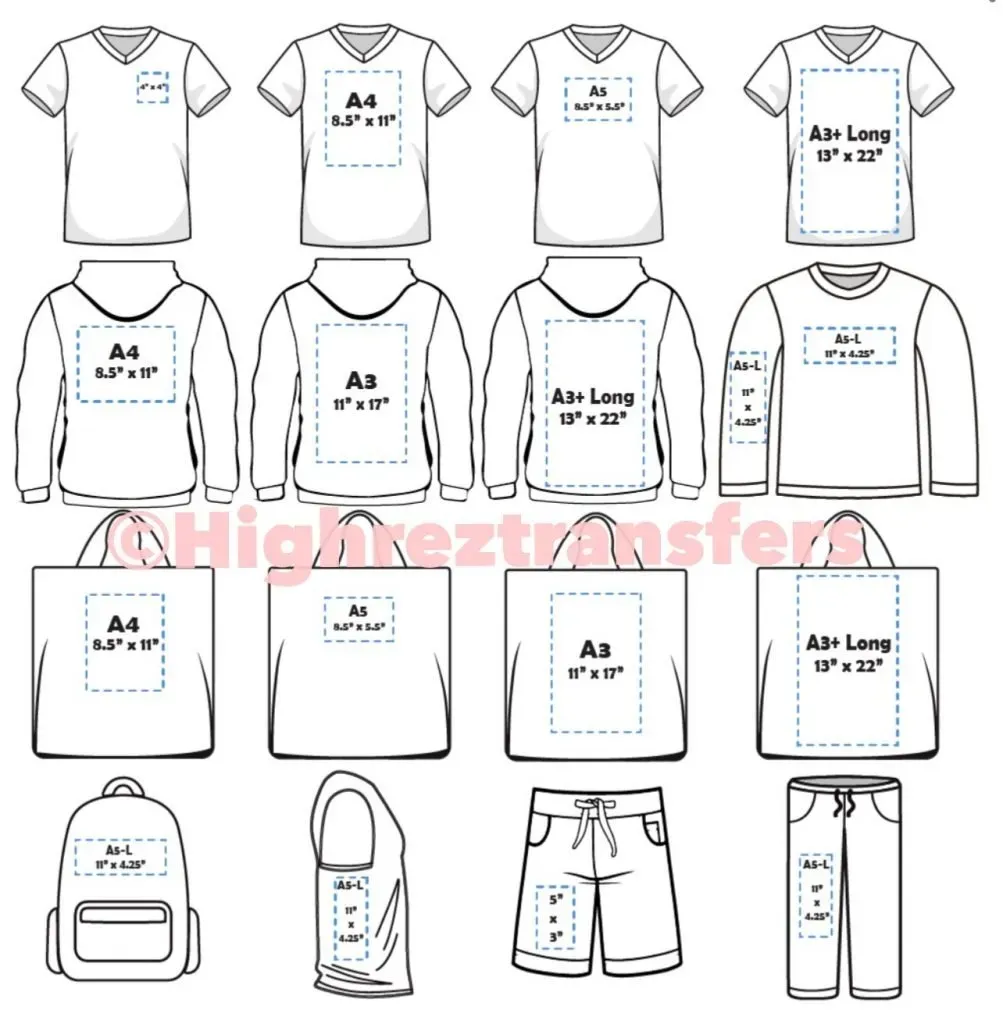

Different garments demand different size targets. Define standard print areas per type—small logos on shirts might be 3×3 inches, while full back prints on hoodies could be 12×14 inches—and use DTF sizing to keep readability and impact consistent. Youth garments often require smaller scales; adult pieces can accommodate larger visuals, but each size decision should respect the fabric’s behavior and the transfer’s edge fidelity.

Size decisions affect color saturation, detail, and legibility. When scaling for various garments, plan for how texture and knit affect edge crispness, and consider how a larger transfer may necessitate higher resolution artwork or a redesigned composition to preserve sharpness in line work and type. Integrate DTF transfer tips into your workflow to maintain consistent results across different product lines.

Optimizing DTF print quality through color management at scale

Color management becomes critical when you resize designs. Use appropriate color profiles and printer calibration to minimize shifts in hue and brightness as the image scales. Vector-based artwork preserves crisp edges on scaling, while raster images should start at high resolution (300 DPI or more at target size) to maintain pixel-level detail, supporting overall DTF print quality.

Ink density and saturation need adjustment when print areas grow. Printing swatches at the target size helps verify color fidelity and edge definition before production runs. Maintaining color consistency across sizes is a key part of the DTF transfer tips and supports a reliable, high-quality output that remains faithful to the original design.

Choosing fabrics and curing methods to boost DTF longevity on fabrics

Fabric type heavily influences how a size-adjusted transfer behaves. Cotton and cotton blends typically deliver strong edge definition and vibrant color when cured correctly, while polyester blends may require adjusted heat and pressure settings to prevent scorching or sheen. Anticipating fabric behavior is essential for DTF longevity on fabrics, particularly when you scale designs to fit different garment panels.

Curing and aftercare are pivotal for durability. Follow recommended heat press settings for each fabric type, maintain even pressure, and consider pre- and post-curing steps to optimize bond strength. Educate customers about proper laundering and ironing practices to maximize the longevity of your DTF transfers on fabrics.

Practical alignment techniques and templates for consistent results

Use reference templates and grids that match your garment dimensions to keep placement consistent across items. This aligns with the DTF alignment guide by providing fixed centerlines and edge landmarks, helping you place the transfer accurately regardless of size.

Placement aids like tape guides or magnetic boards help fix the transfer during pressing. Dry-fit on a sample garment, verify how the design sits when flat and when worn, and adjust before bulk production. Standardizing templates and maintaining documentation of successful settings further reinforces consistent results across production runs.

Troubleshooting size-related DTF transfers: common issues and fixes

Misalignment after heating often traces back to inadequate fixation or shifts during the heat cycle. Revisit alignment setup, secure the transfer with additional masking or magnets, and re-check centerpoints and seam references before pressing. If color shifts occur after scaling, revisit color profiles and print test swatches at the target size to restore fidelity, a core part of practical DTF transfer tips.

Other common issues include edge cracking, ghosting, or warping on curves. Ensure even heat distribution and avoid overloading ink density, adjusting cure time and temperature as needed. On curved areas like sleeves, consider smaller panel sizes and dedicated placement aids to prevent distortion, while leveraging the DTF alignment guide to maintain precision.

Frequently Asked Questions

What is DTF transfer by size and how does sizing affect alignment and print quality?

DTF transfer by size means resizing a design to fit different garments while preserving proportion. This sizing can influence alignment with seams, pockets, or logos and impact edge clarity and color saturation. Use an DTF alignment guide, test prints, and predefined target print areas to maintain consistent print quality across sizes.

How do I use the DTF alignment guide to ensure accurate transfers when resizing by size?

Follow the DTF alignment guide by creating a reference grid or crosshair that matches your garment dimensions, using placement aids to fix the transfer, scaling uniformly, and marking key landmarks (like collar seams and sleeve lines). Dry-fit checks help verify alignment before bulk production.

What sizing practices help maintain DTF print quality across different garment sizes?

Keep the original design’s aspect ratio, define standard target print areas per garment type, and avoid upscaling low-resolution artwork. Use high-resolution files (300 DPI or more) or vector art, and run test swatches at the target size to preserve DTF print quality.

How does fabric type impact DTF longevity on fabrics when printing by size?

Fabric type affects adhesion and durability. Cotton and blends typically tolerate size changes well, while polyester may require different heat/pressure settings. Proper curing, consistent heat and time, and clear care instructions help maximize DTF longevity on fabrics across sizes.

What are common issues with DTF transfer by size and how can I troubleshoot them?

Common issues include misalignment, edge peeling, color shifts, ghosting, and warping. Troubleshoot by tightening alignment before pressing, ensuring even ink density, verifying color profiles, testing at the target size, and using appropriate placement aids for curved areas.

How can I optimize DTF print quality when resizing designs for multiple garments?

Optimize by calibrating color profiles for your printer and media, deciding between vector and high-resolution raster art, and printing size-specific test swatches. Maintain consistent ink density and verify edge fidelity to keep DTF print quality high across sizes.

| Aspect | Key Points |

|---|---|

| Definition | DTF transfer by size resizes a design for different garments while preserving proportion, placement, and print integrity. |

| Why size matters | Placement with seams/logos/sleeves, edge sharpness, color richness, and durability are influenced by transfer size. |

| Core considerations | Proportion, placement, fabric stretch, resolution, ink density, and scalable prepress workflows to avoid blur or pixelation. |

| Prerequisites | Garmet selection (cotton/blends), RIP software (vector-preserving; 300 DPI), transfer film/powder, test prints, and the DTF alignment guide. |

| Alignment techniques | Reference templates, placement aids, uniform scaling, landmark references, and dry-fit verification. |

| Sizing/Scaling & Proportion | Maintain aspect ratio; avoid extreme upscales with limited resolution; define target print areas per garment type. |

| Print quality & color | Color profiles/calibration, vector vs raster handling, ink density, and test swatches for color accuracy. |

| Curing & longevity | Appropriate heat/pressure, even application, pre/post-curing steps, and care instructions to extend life. |

| Fabric types impact | Cotton vs blends vs polyester: adjust heat/pressure; dark fabrics may require a white underbase. |

| Troubleshooting | Misalignment, edge cracking/peel, color shifts, ghosting, warping; fixes include re-alignment and adjusted settings. |

| Practical tips | Templates library, documented settings, QC checks, training, and ongoing workflow optimization. |

Summary

Conclusion: Mastering DTF Transfer by Size for Longevity and Quality